Swirly

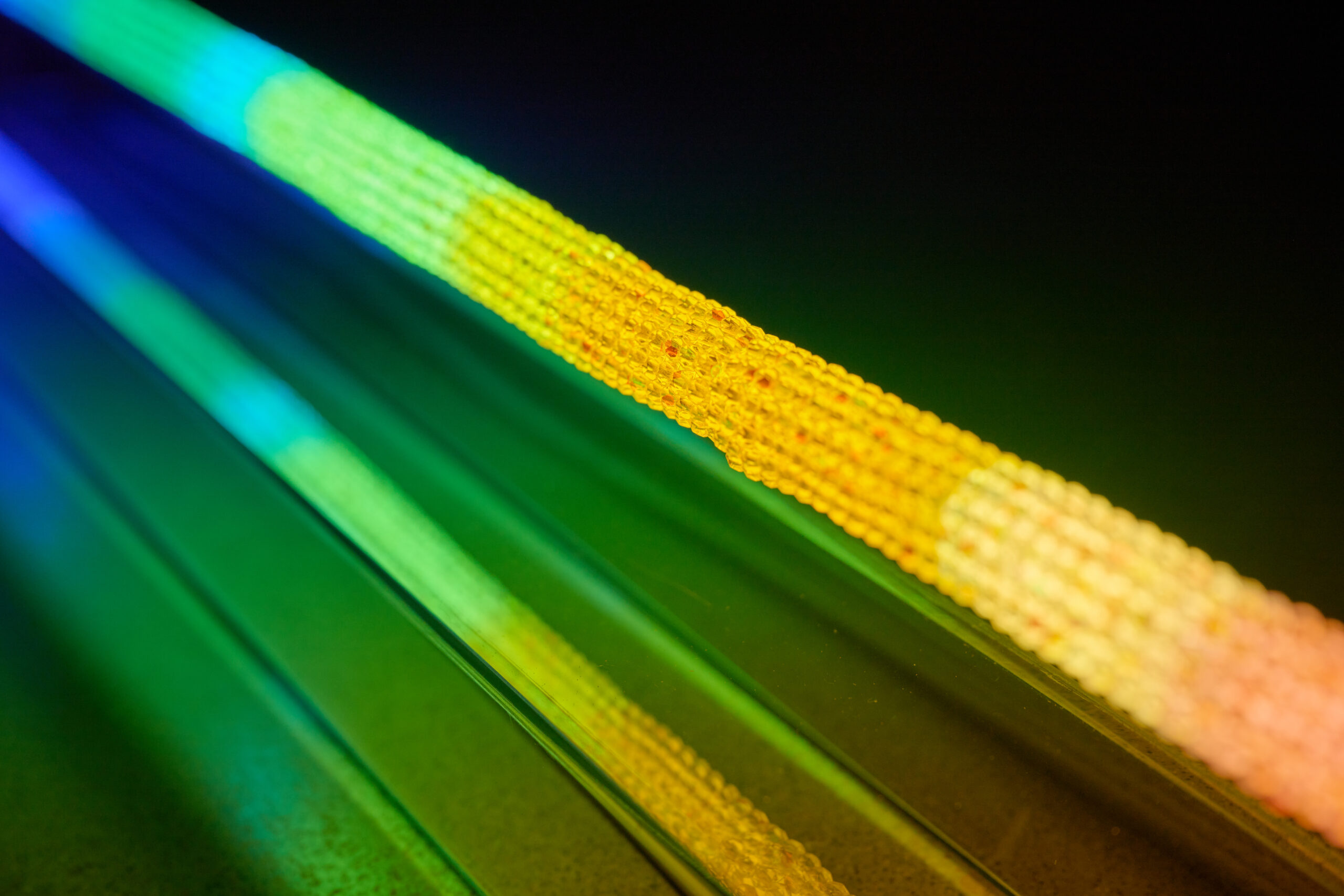

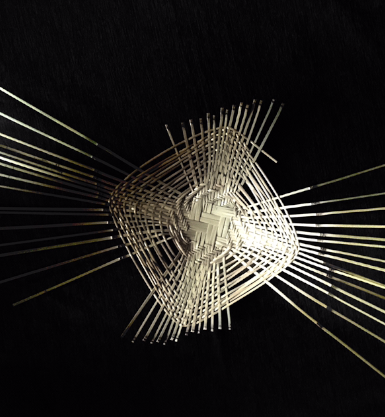

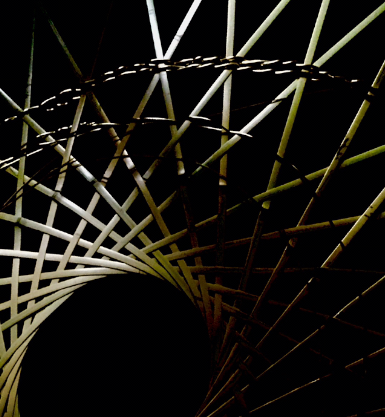

Through the deconstruction and reinterpretation of the traditional bamboo steamer, Lawrence has created two lighting designs to capture his fond memories of family gatherings and moments of daily lives in Hong Kong’s traditional dim sum restaurants (yum cha). One of the details of the chandelier is the splitting and opening up of the original bamboo into six divisions, which resonates with the first step of the traditional bamboo crafting process. As the bamboo pieces are steamed and softened, they are curved into circular shapes, which became the steamer-shaped structure at the end of each branch of the chandelier. The whole fabrication is precisely borrowed from the process of the making of traditional bamboo steamer. The lighting highlights the curves of the bamboo structure, which also brings out the malleable quality of the bamboo.

Story of the Traditional Craft

Dim sum is nowadays synonymous to the Hong Kong local culinary culture. Originated from the south, bamboo steamers were first used for cooking grains, but were later extended to the cooking of meat and fish. In the past decades, these mouthful bites of delicacies which came to be known as dim sum have been cooked and served separately in individual bamboo steamers.

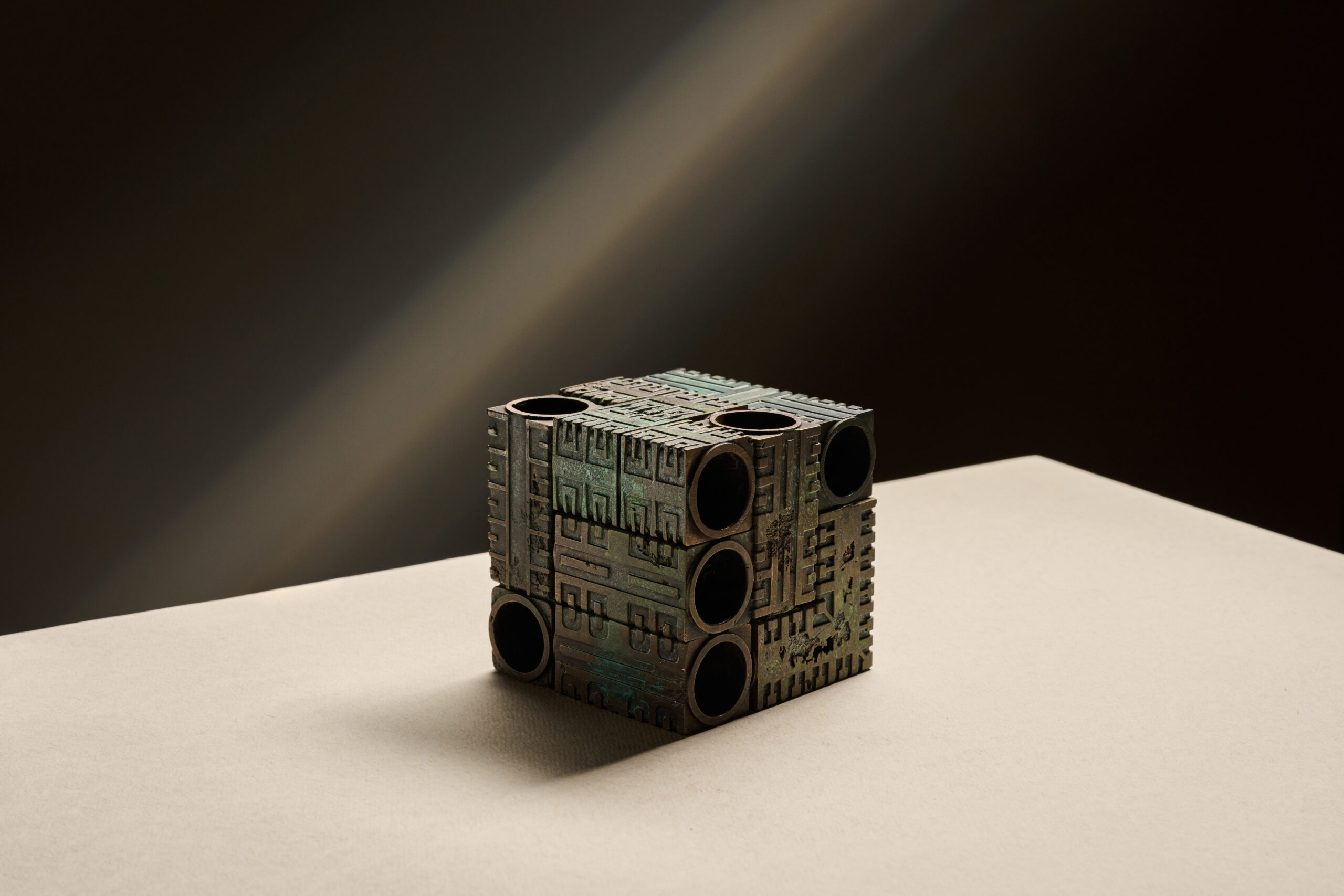

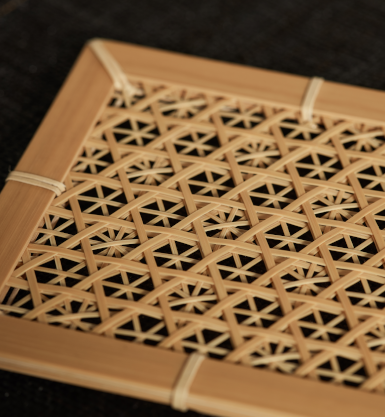

Composed of an open-weave bottom and a domed lid, the structure of the bamboo steamers allows steam to travel through the bottom and circulate, while the domed lid prevents the steam to escape. Given the density of the bamboo, moisture from the steam is retained without causing any condensation which would dampen the food, while locking in the flavor and keeping its moisture and tenderness. One of the unique features with this cooking method is that the bamboo steamers can be stacked one on top of another, allowing multiple dishes to be cooked at the same time. The scent of the bamboo can also diffuse a subtle aroma and add flavor to the food being steamed in the container. The traditional craft of bamboo steamer is a prime example of the modern design principle of “form follows function”.

Making Process

To craft a durable bamboo steamer that makes use of the various bamboo components requires the accumulated experience of the craftsman. To commence, the craftsman would use his hand to feel the different bamboo parts to make sure that the thickness and sizes of the pieces are equal. Then the skin of the bamboo has to be peeled off, which will be used for the cover of the steamer. The remaining bamboo parts will be used for making the bottom, the inner and outer frame. During the crafting process, the bamboo will be bent by hand, and the force exerted in the bending would depend on the thickness of each bamboo piece. The structure is then fixed by the “bamboo nails” created using the remains from the bamboo sticks. Each and every step reflects the craftsman’s intricate skills. To acquire the technique in crafting a steamer from scratch would require at least three to four years of apprenticeship.

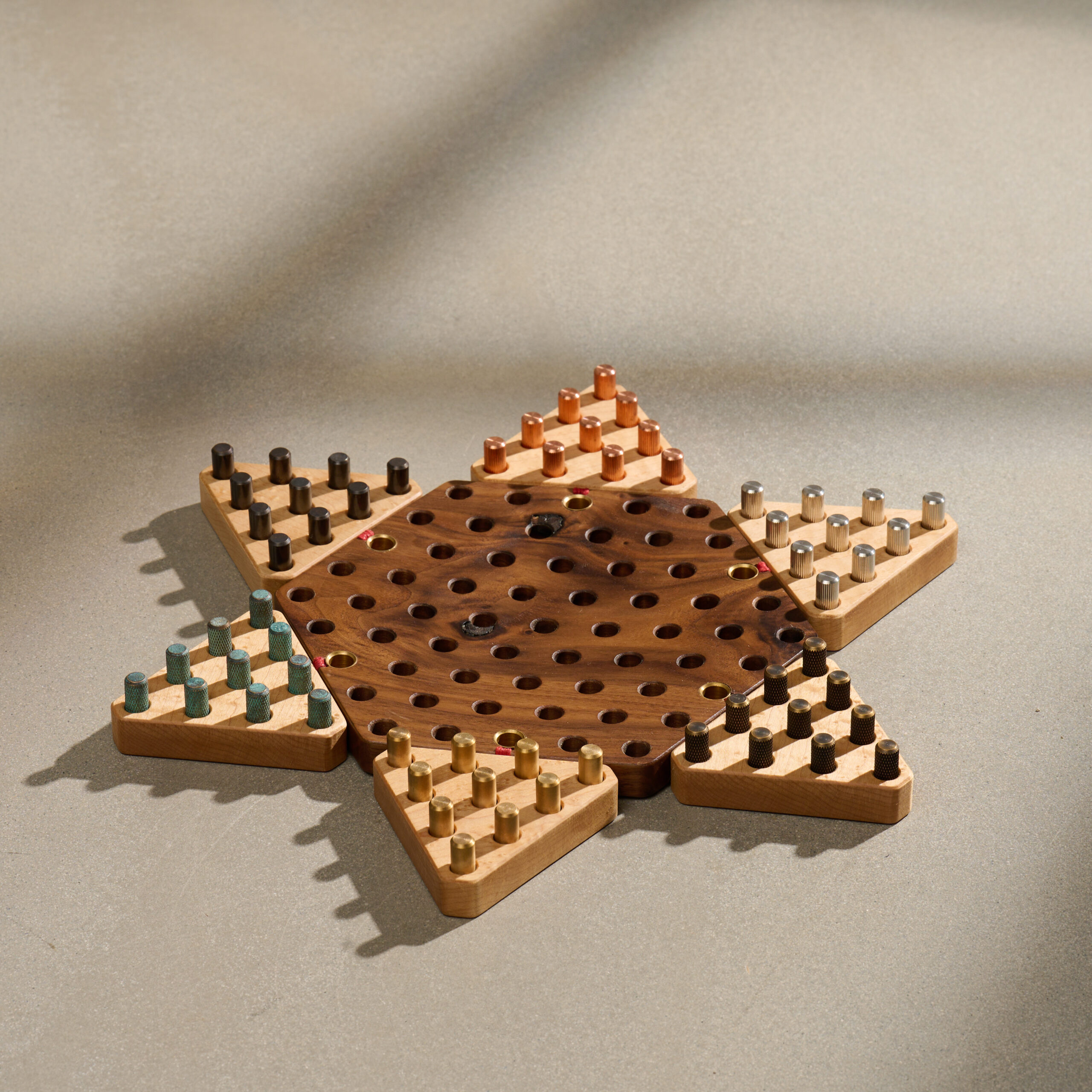

Artworks from same series

OTHER WORKS FROM EXHIBITION

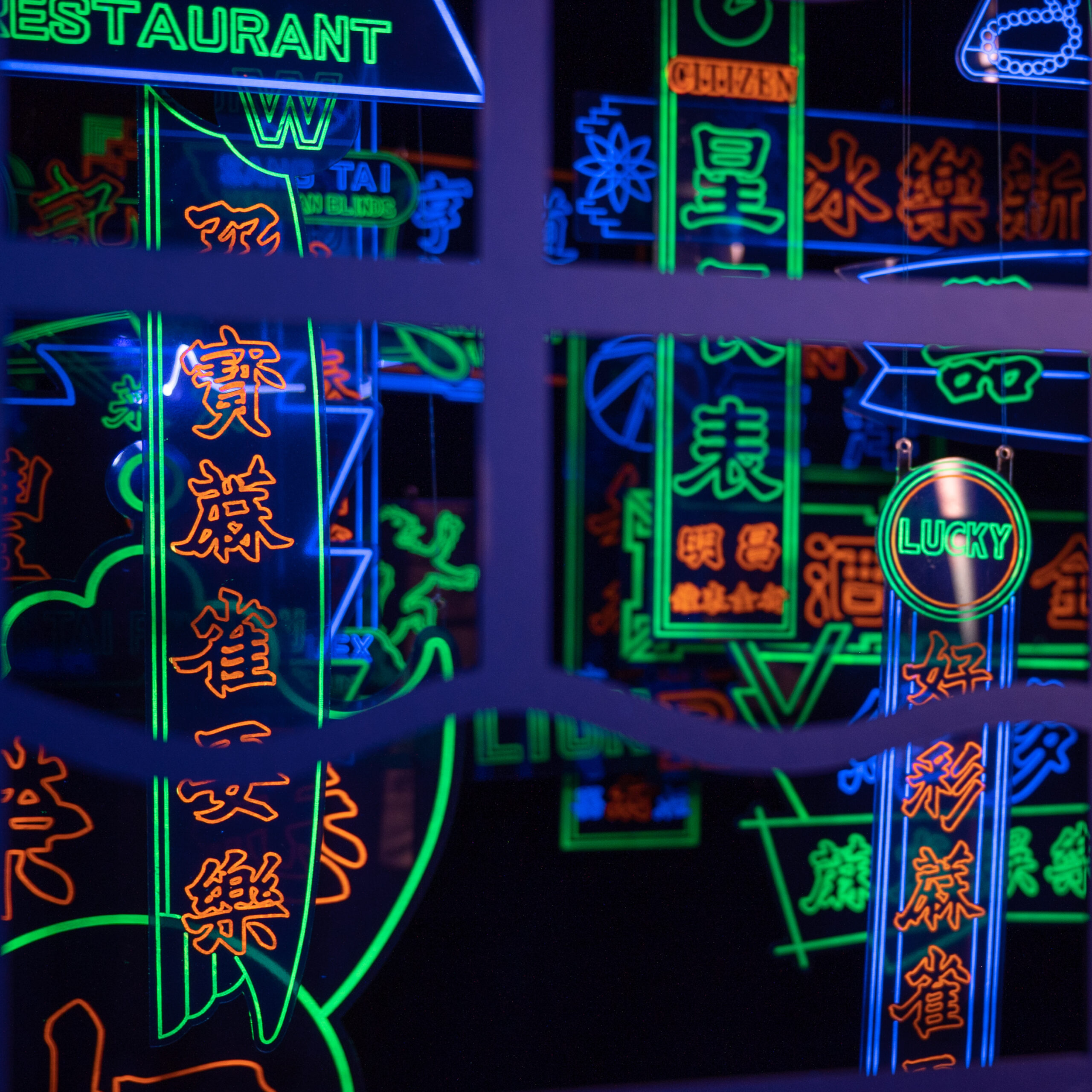

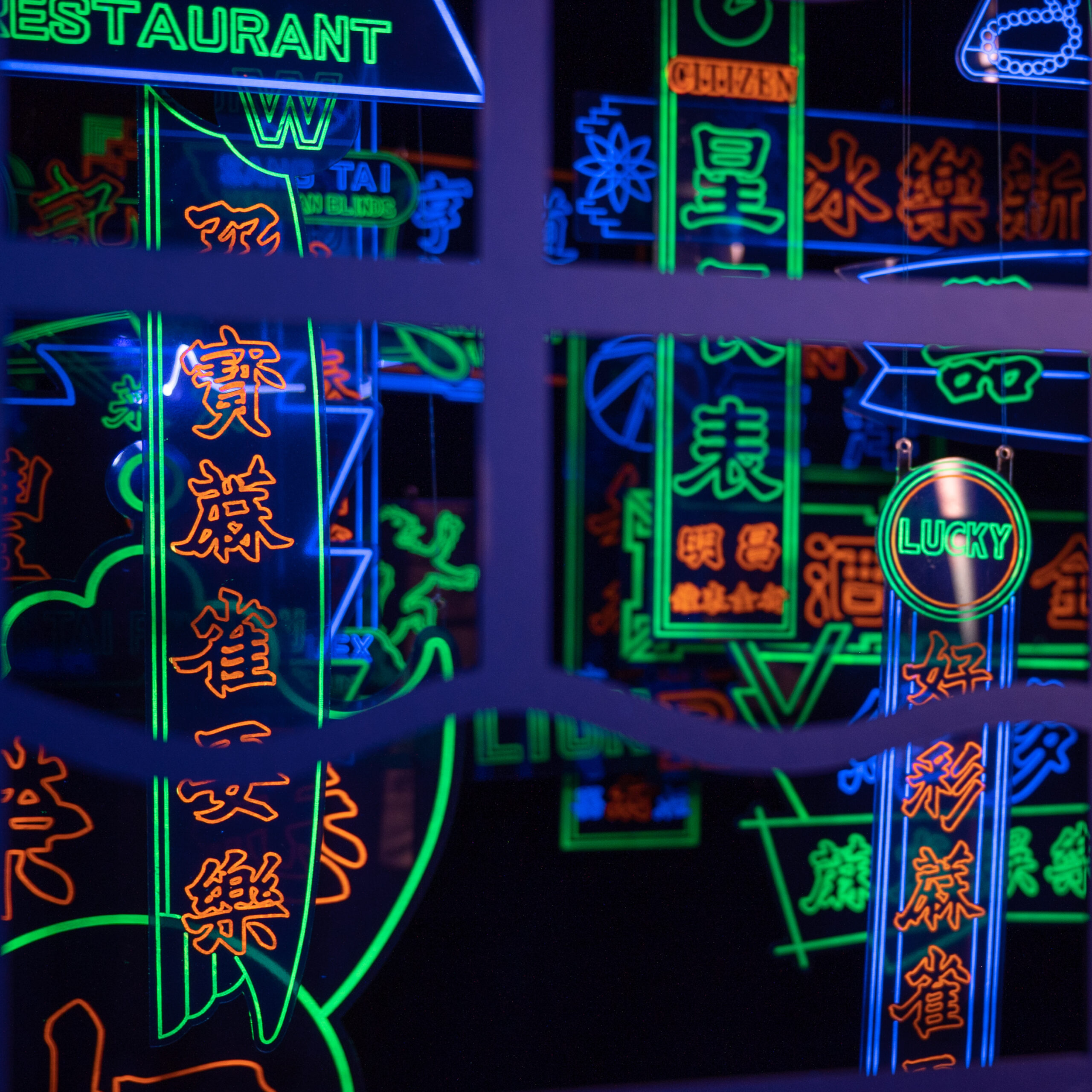

Auspicious Horizons

Yue Kee Rattan Factory & Ahung Masikadd & Barnard Chan & Cecilia Lai