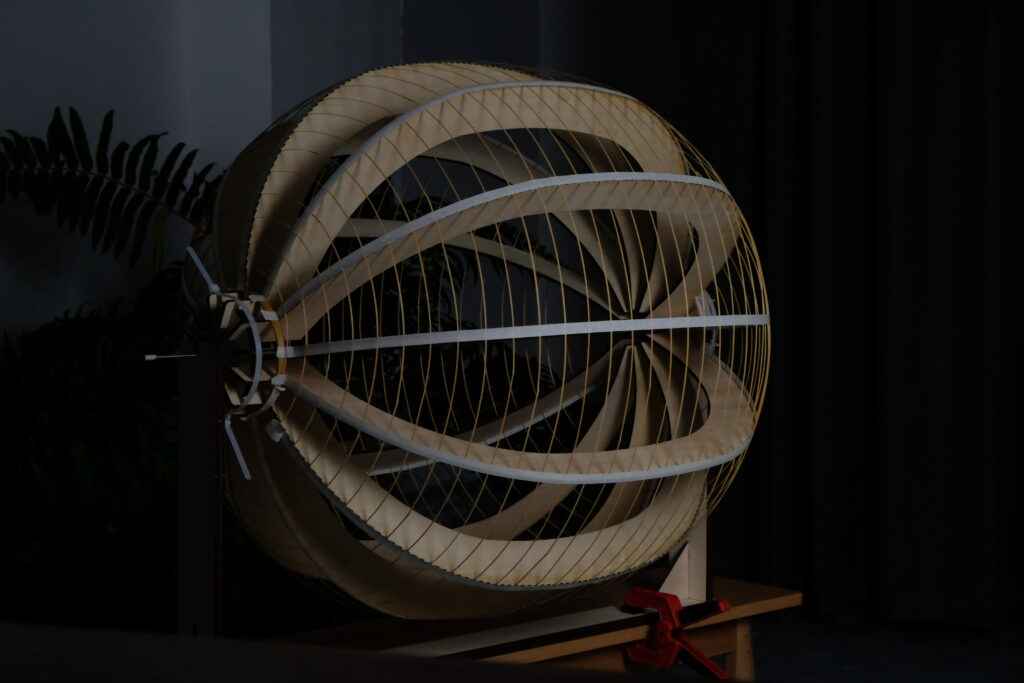

Lantern

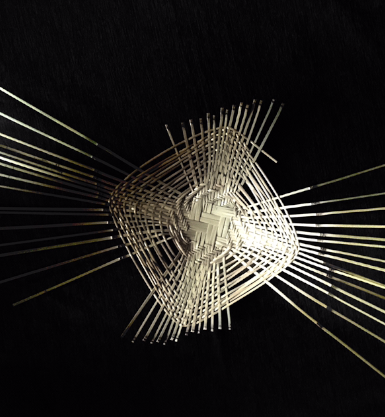

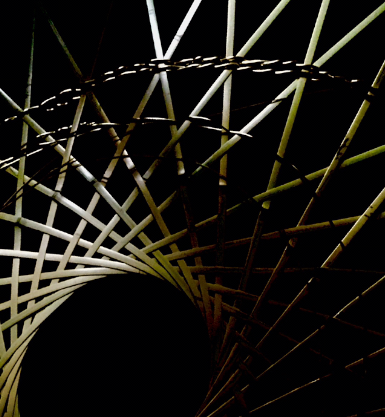

The design is with reference to the classic Japanese lantern combining contemporary aesthetics to allow light beams gently penetrating the Chinese rice paper into the space. Ting condensed the traditional making process into five steps: material touch-ups, structural assembling, paper-mounting, paper-cutting, and infusing (laying paper creases).

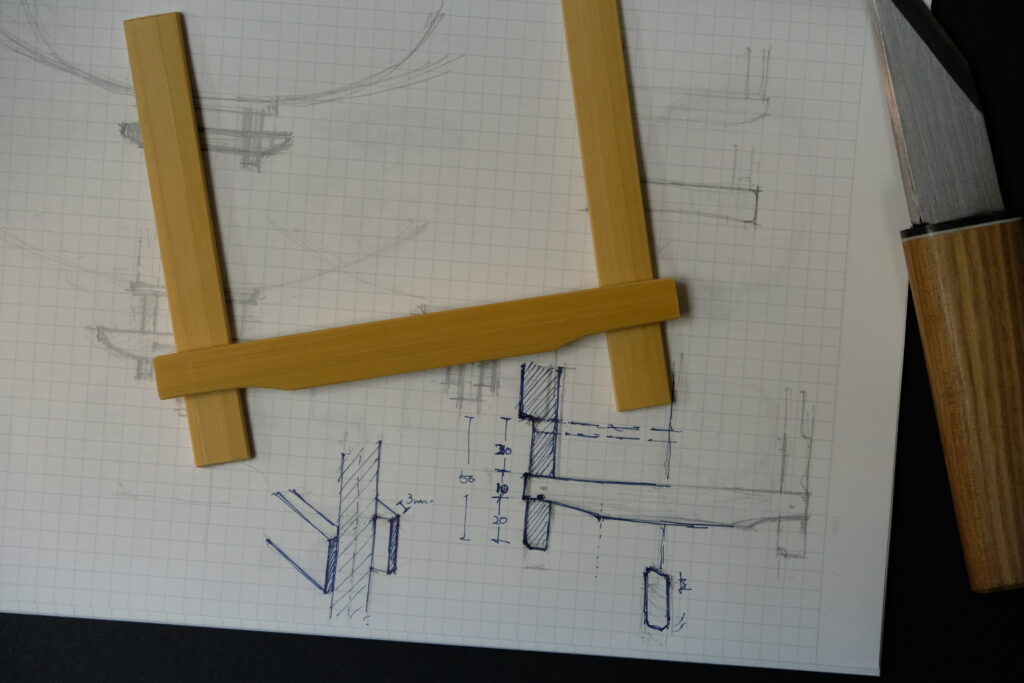

Making Process

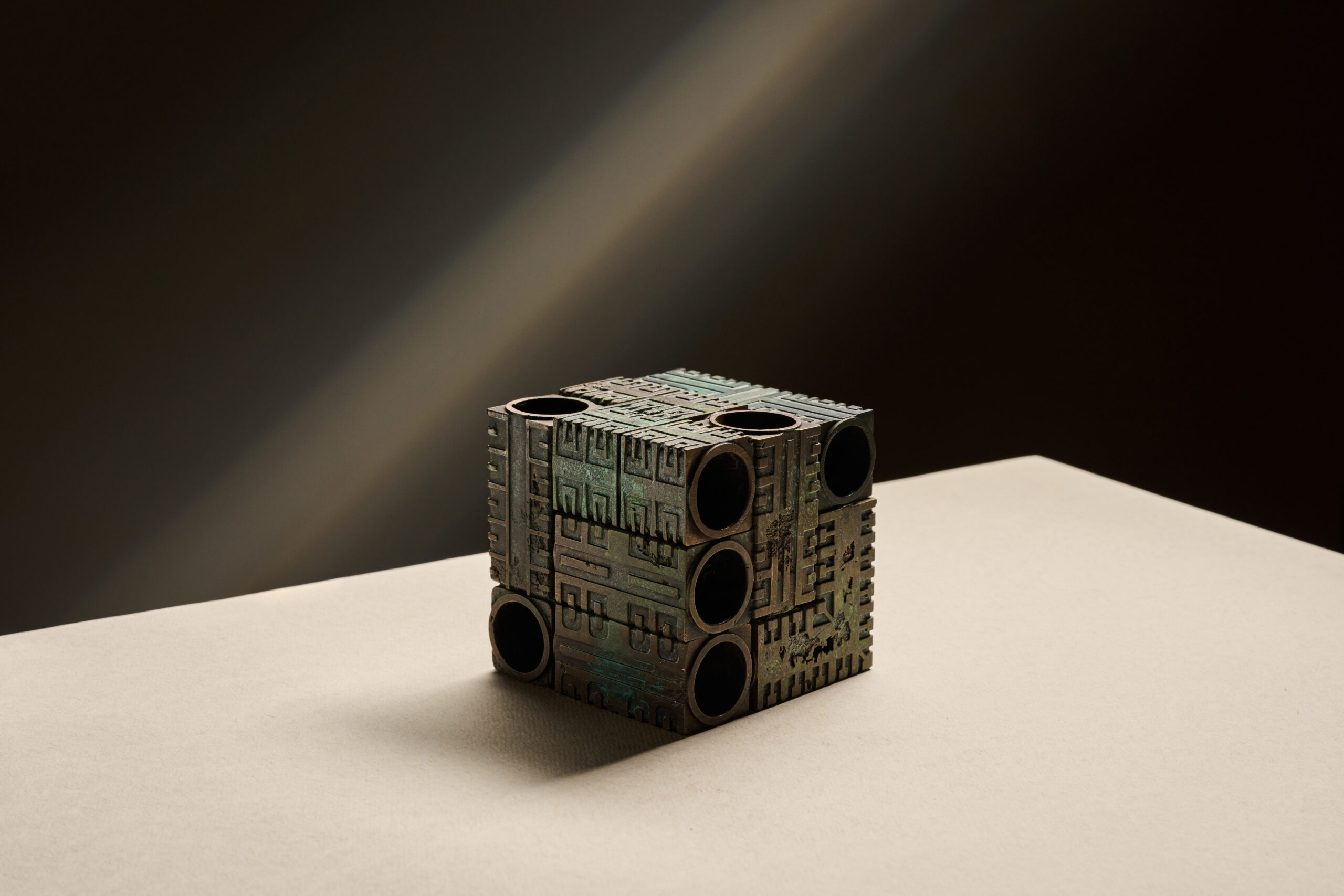

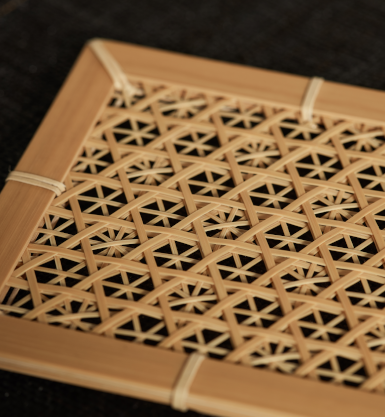

The lantern is made of bamboo strips with high pliability, which is more durable than lanterns made more commonly with bamboo cores. The frame is formed by twisting a piece of bamboo strip in a spiral shape, a traditional bamboo crafting technique. Most of the Japanese lanterns have a softer horizontal structure for storage purposes, while Chinese lanterns have a sturdier vertical structure as a foundation. Ting For Chun incorporates the idea of Chinese lanterns, adopting the technique of tenoning to create a strong bamboo structure in the center, minimizing the extent of swinging.

Artworks from same series

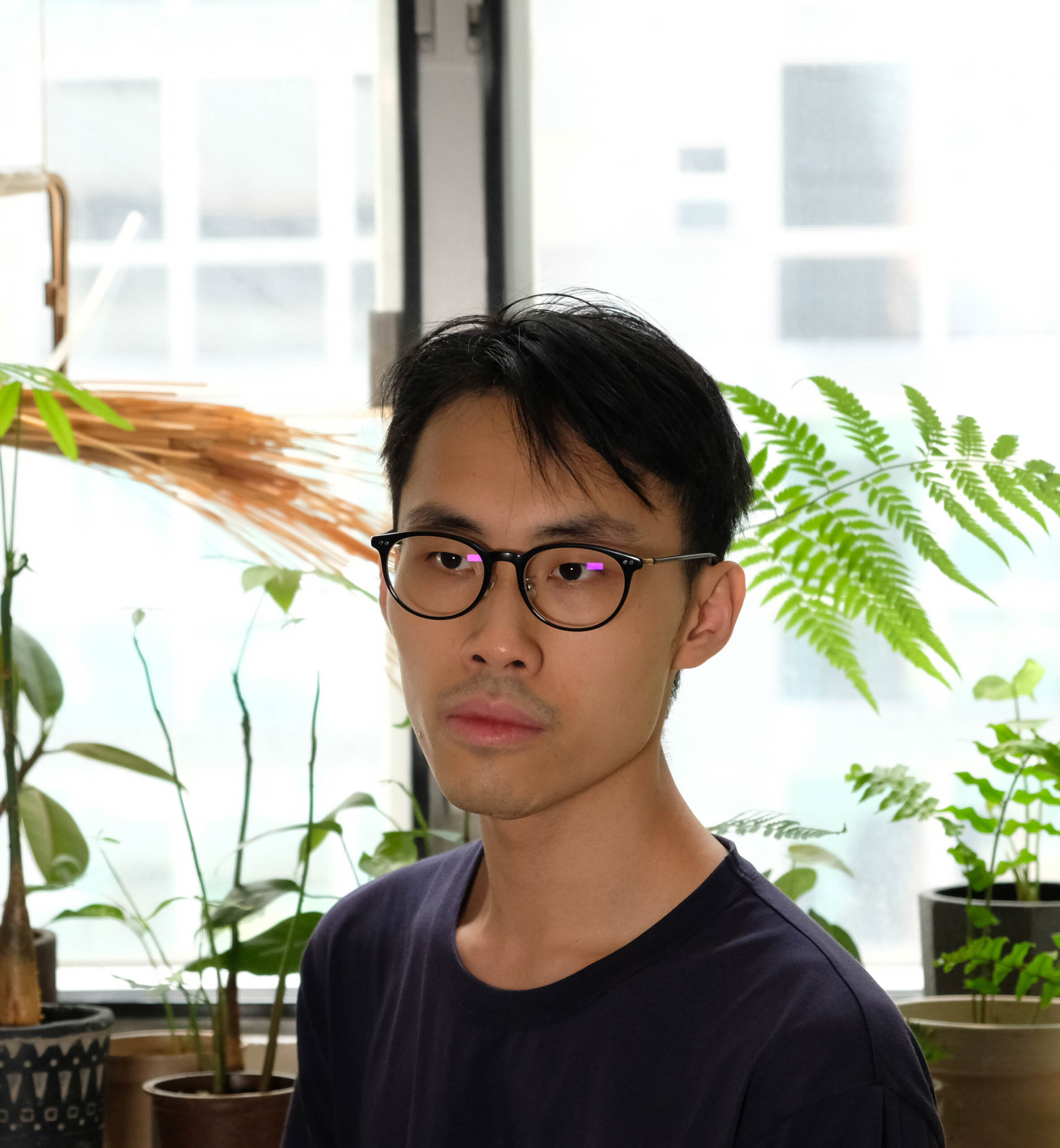

Craftsman

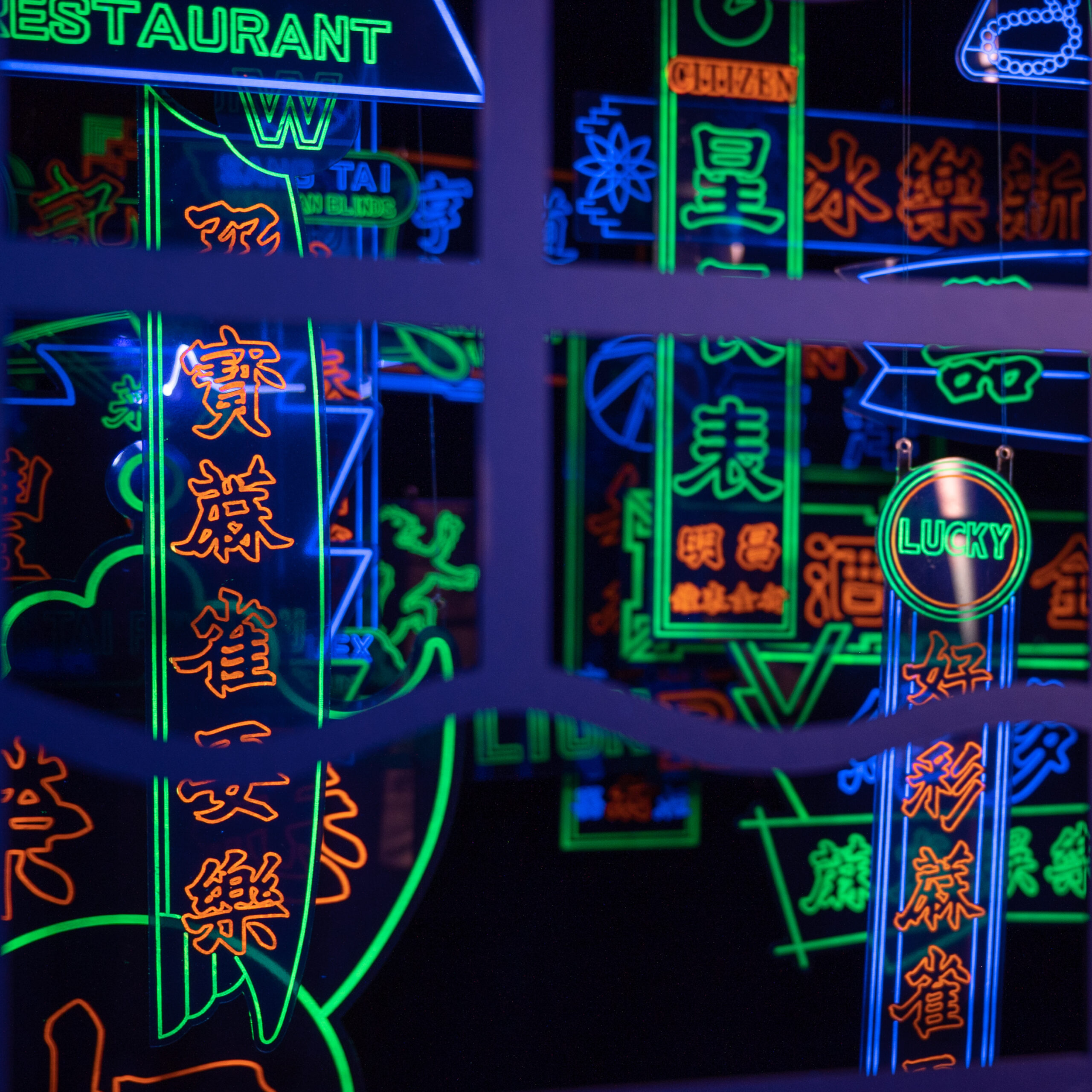

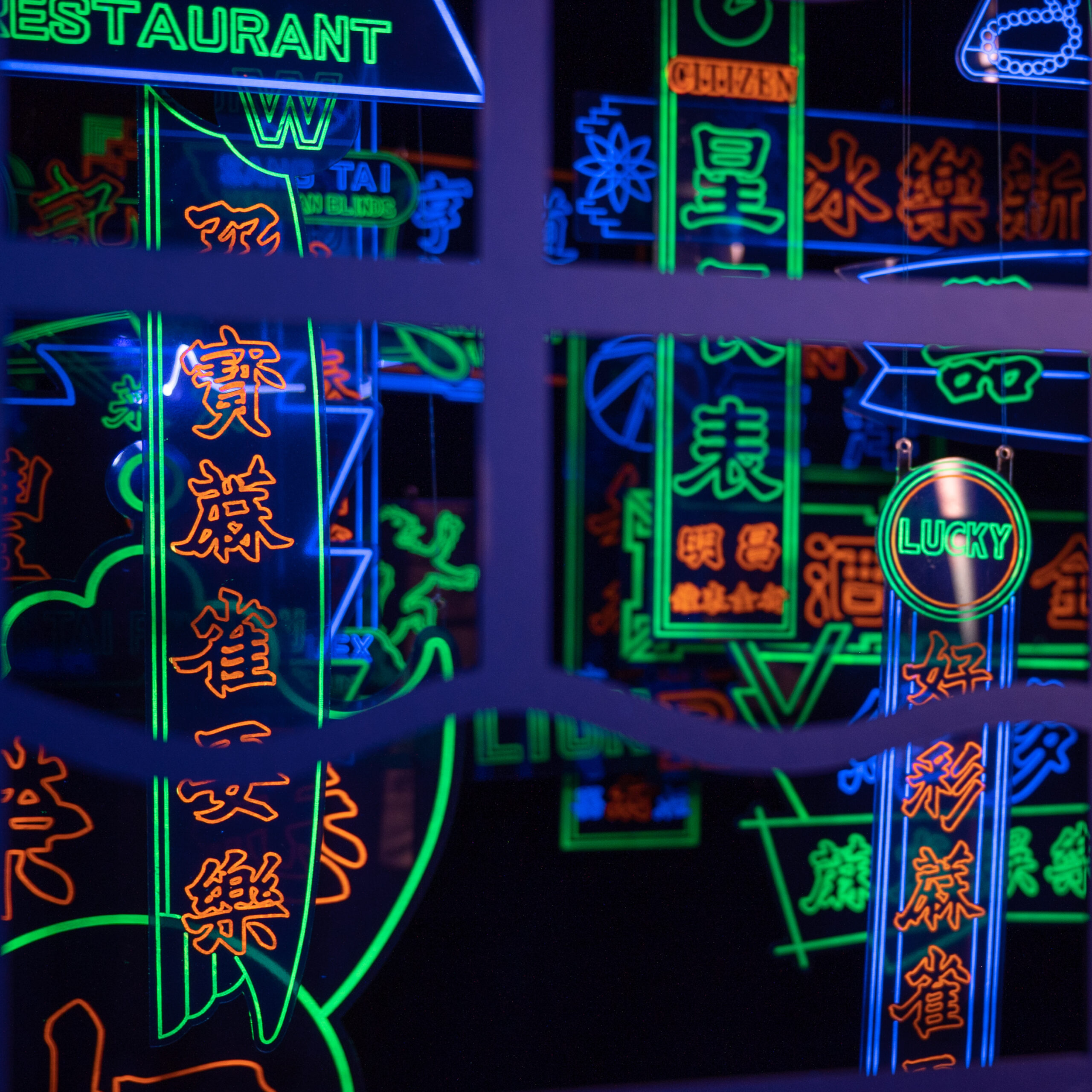

OTHER WORKS FROM EXHIBITION

Auspicious Horizons

Yue Kee Rattan Factory & Ahung Masikadd & Barnard Chan & Cecilia Lai