Hong Kong Mosaic

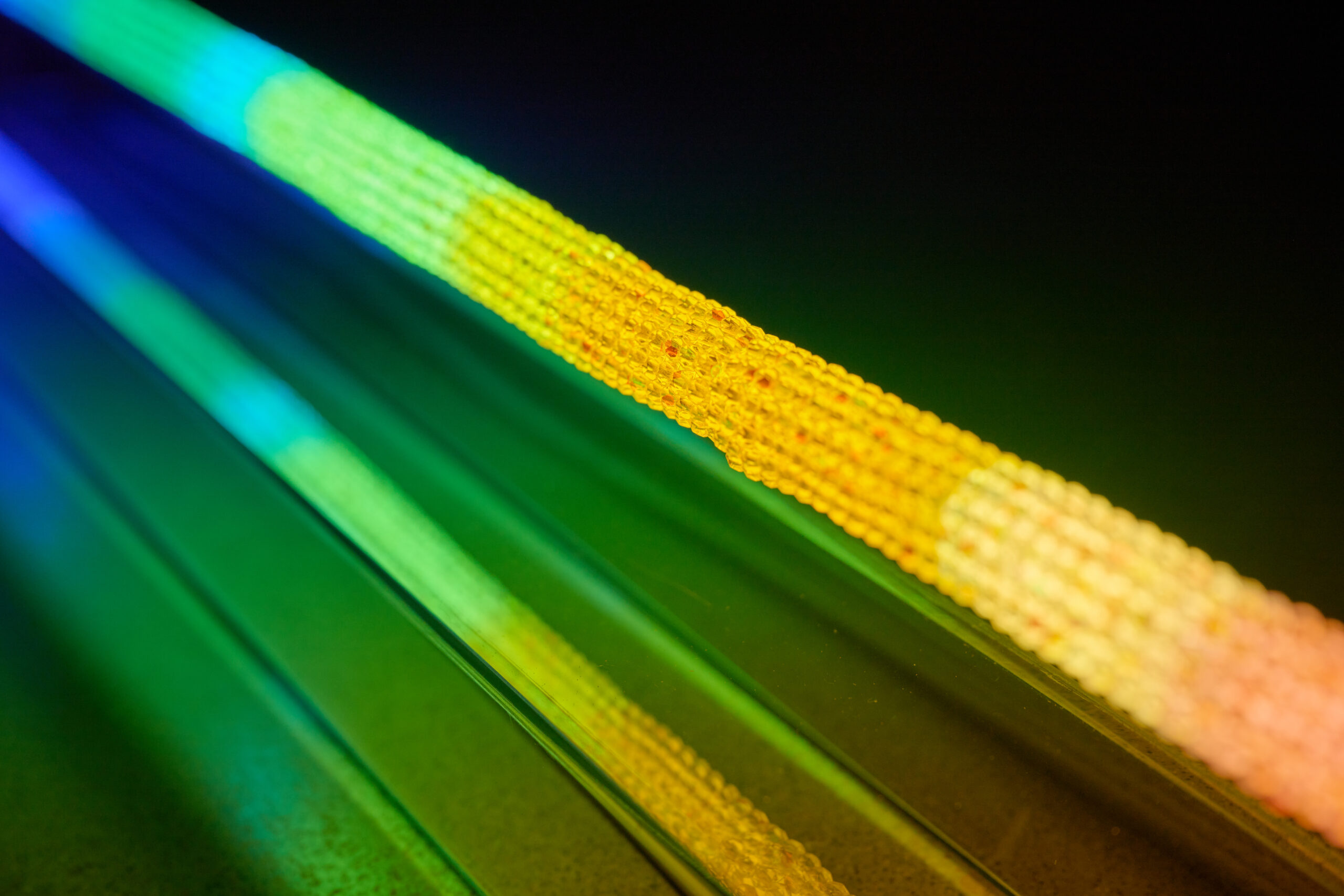

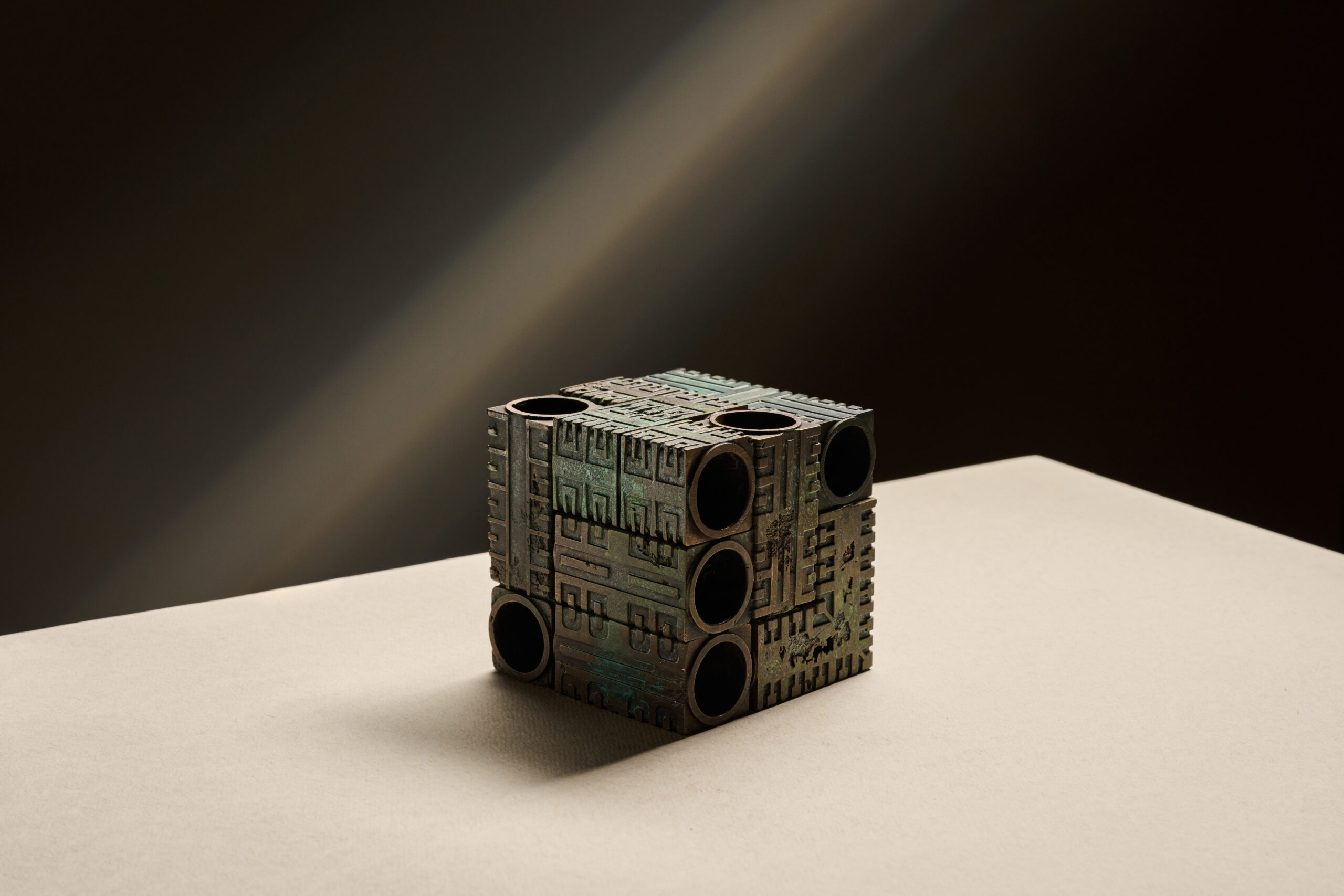

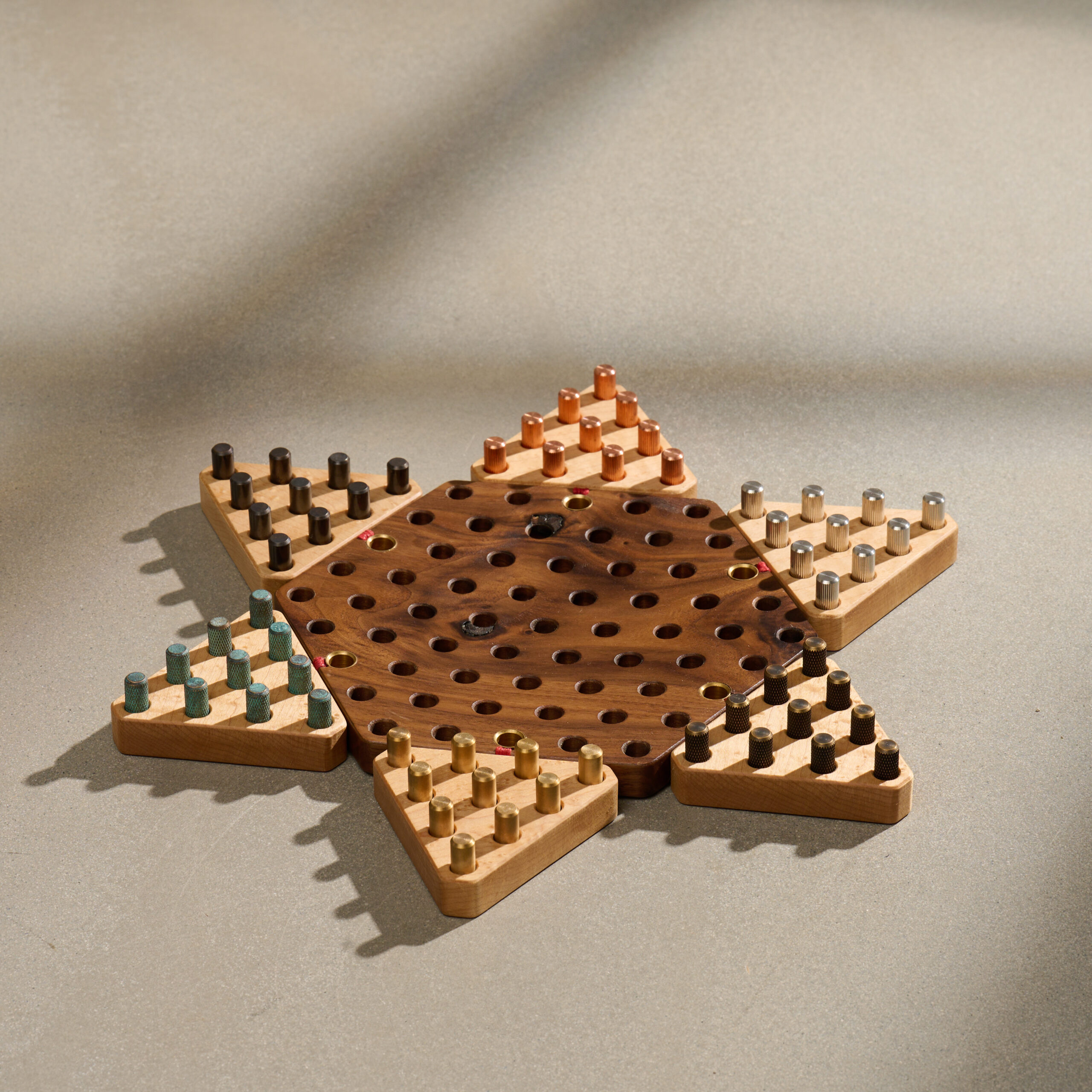

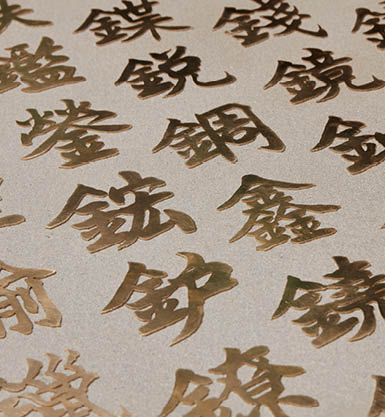

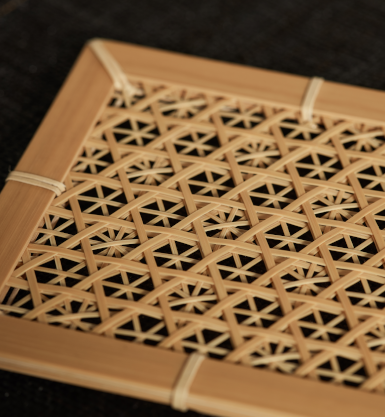

Inspired by the classic mosaic pattern found in “Tong Lau'', typical tenement buildings in Hong Kong, this collection employs the natural hues of wood, forming various mosaic patterns using the traditional Japanese marquetry technique: Yosegi-zaiku. Objects formed were cut into cubes for decorating plates and even sliced into thin decorative veneers for adorning wooden crates. Through woodturning, objects are transformed into myriads of lines and forms, with a very high degree of flexibility on a lathe, allowing for wide-ranging possibilities and variations. Interestingly, there is no fixed definition of a finished piece, leaving room for imagination for creating subsequent works.

By combining various kinds of woods and shaping them via woodturning, Linus K and Chow Man hope to display the mosaic pattern from plane to three-dimensional and take on a new form, revealing its beauty from an unseen perspective.

Making Process

The making process of “Hong Kong Mosaic” involves the following steps: “material selection”, “cutting”, “assembling”, “adjustment”, “sawing”, “woodturning”, and “sanding and finishing”. Traditional craftsman Linus K and contemporary artisan Chow Man selected maple, teak and walnut wood to produce different shades of the original wood grain. After “cutting” and “sawing” the materials to the right size, different timber shades are assembled and glued together. The length and size of the semi-finished product are adjusted for consistency by removing uneven and redundant parts both manually and by machinery. After that, the finished patterned wooden blocks are then cut into various sizes in preparation for “woodturning”.

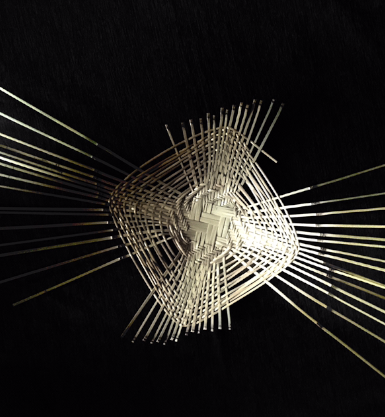

Holes are drilled at the center on both ends of the wooden block to facilitate its placement on the lathe. While the spindle is activated, shapes are cut and molded with a chisel from different angles based on the pre-designed shape of the piece. During the woodturning process, the depth of cuts is checked with a pair of outside calipers. Traditional chisels and modern chisels with replaceable tips are interchanged to create the desired shape and lines. Finally, the process of polishing and finishing marked the completion of the craftwork.

Artworks from same series

Craftsman

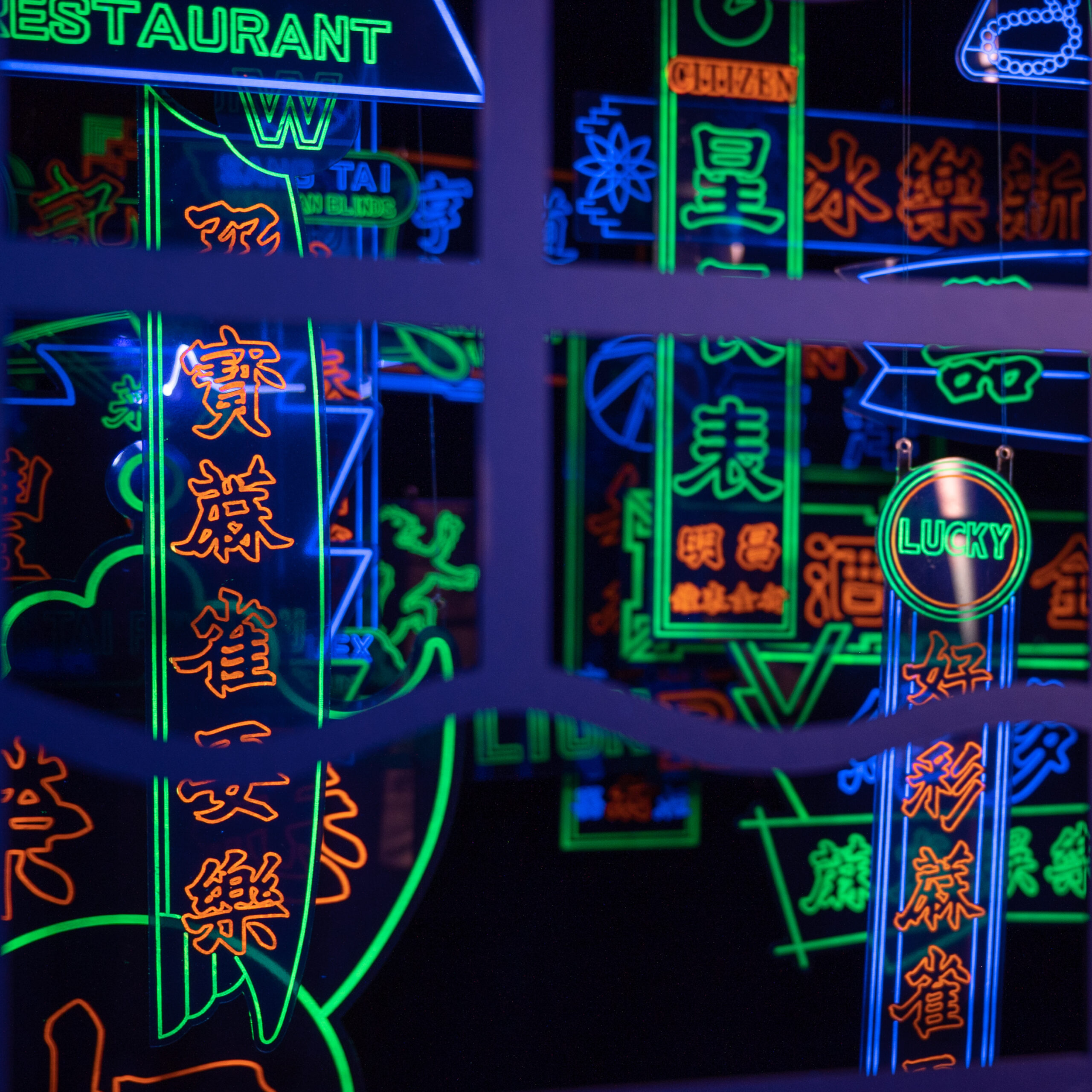

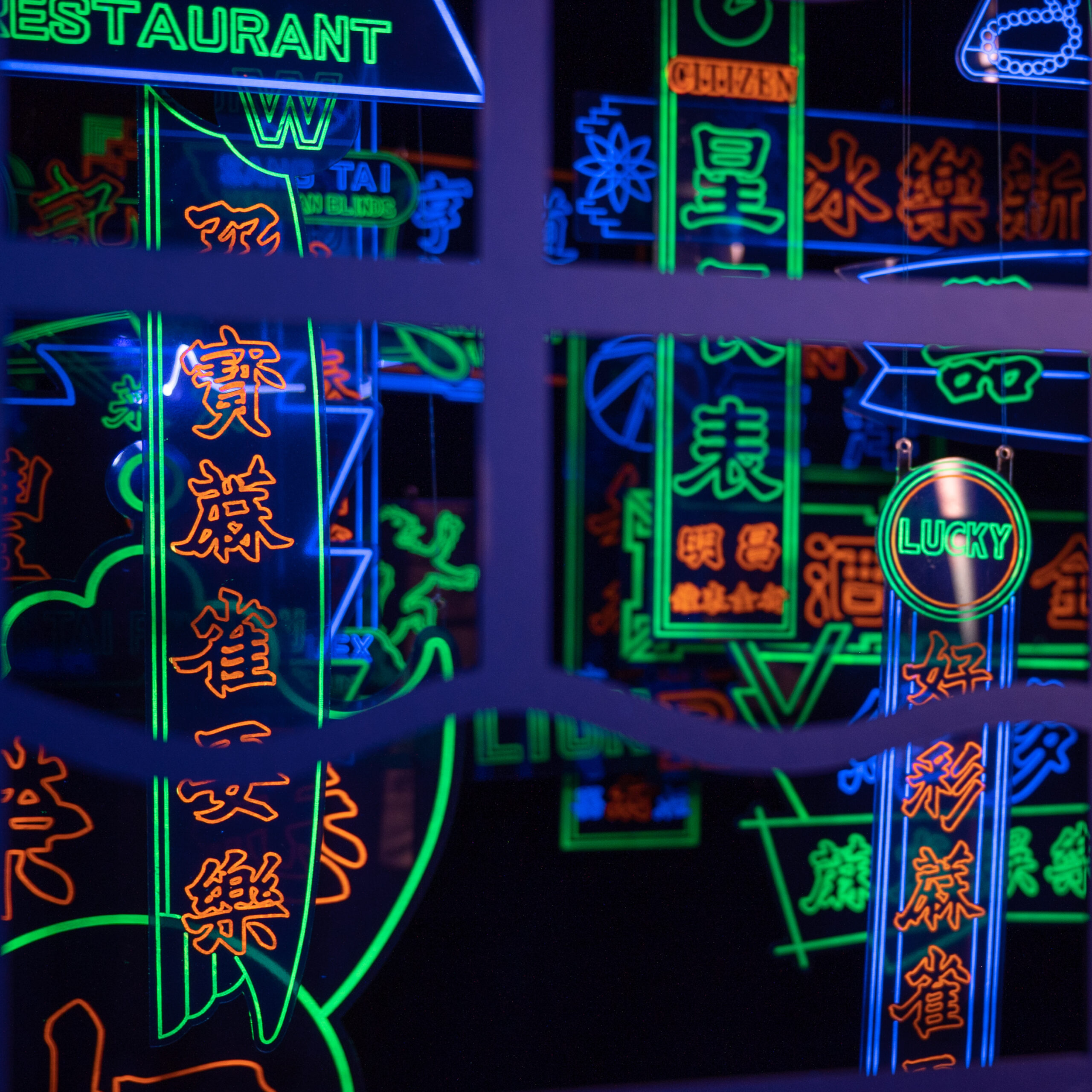

OTHER WORKS FROM EXHIBITION

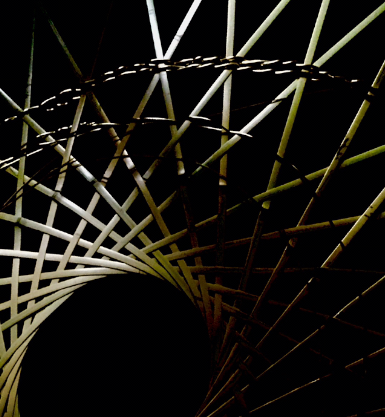

Auspicious Horizons

Yue Kee Rattan Factory & Ahung Masikadd & Barnard Chan & Cecilia Lai