Alembic Copper Still

Dimple Yuen and Ivan Chang teamed up with traditional craftsmen Luk Shu Choi and Luk Keung Choi to refine a copper alembic still by adapting techniques from handcrafting herbal tea brass vessels. Dimple and Ivan uphold the respect for traditional copperware and distillation techniques while implementing the spirit of "Made in Hong Kong" to the entire making process, from the research and development to experimentation of the distillation formula.

The high thermal conductivity of copper plays a vital role in removing impurities during the distillation process, which explains why copperware has always been used for gin making. Although some modern stills use stainless steel for economic purposes, Dimple and Ivan have insisted on using copper and follow the more traditional spirits brewing process to produce premium spirits.

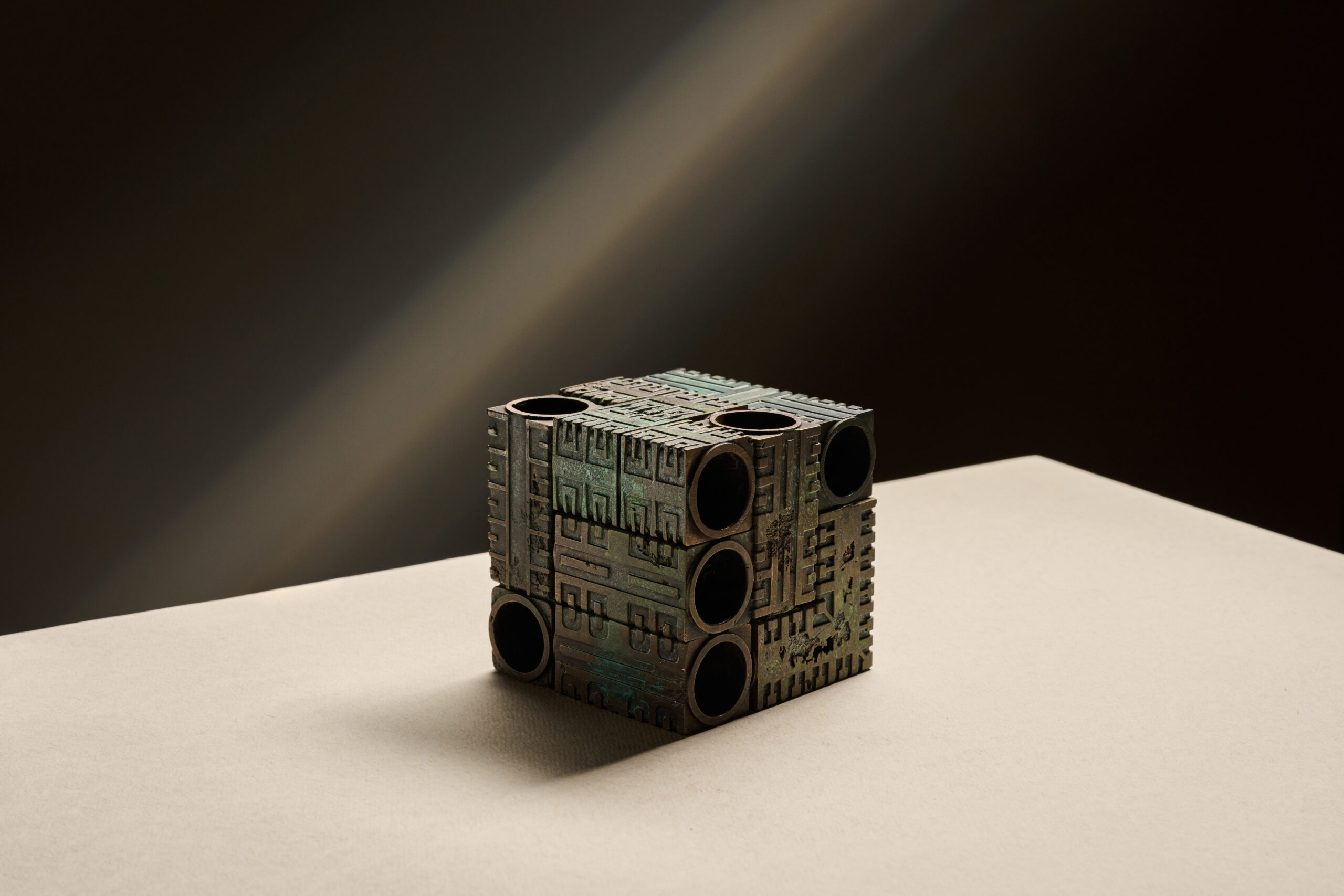

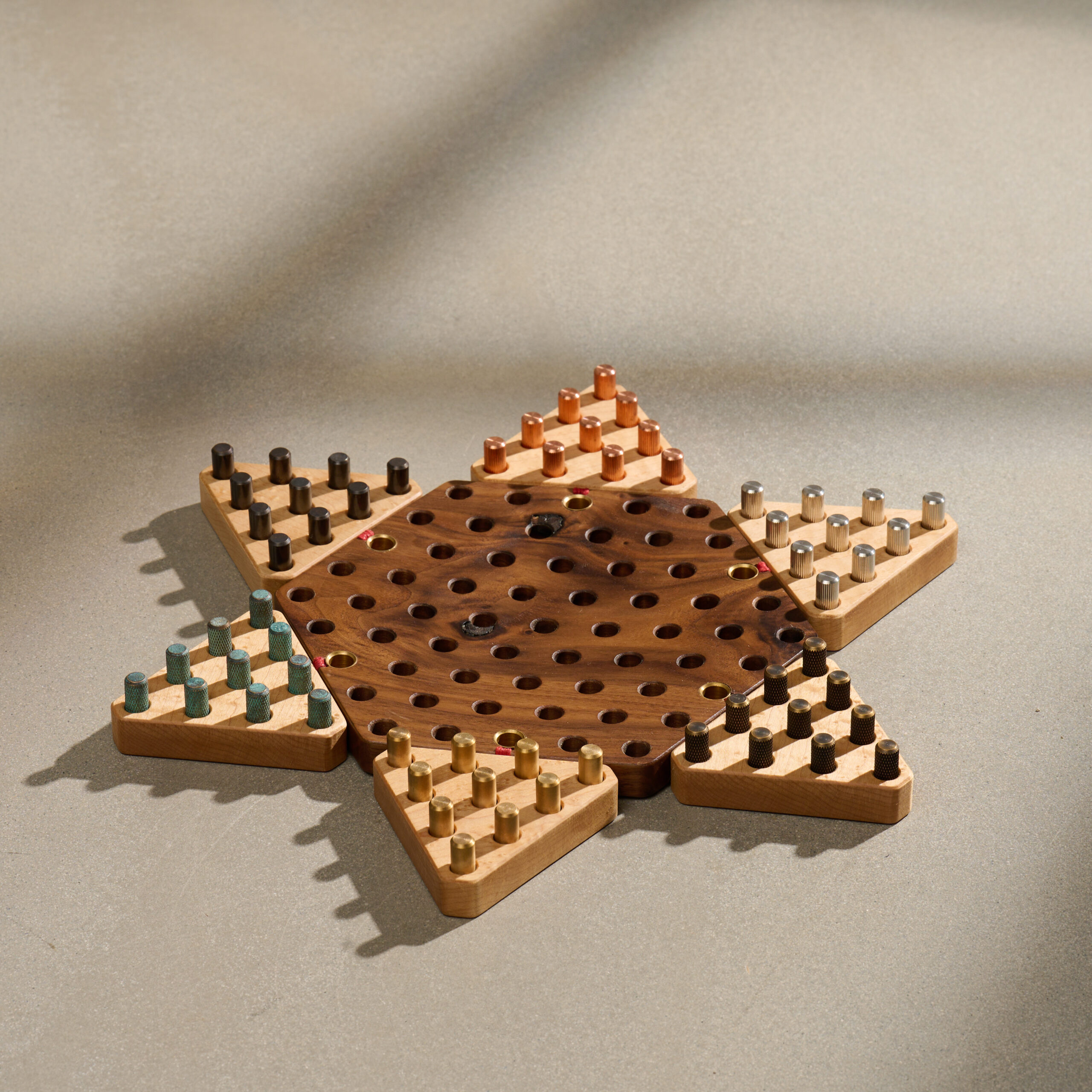

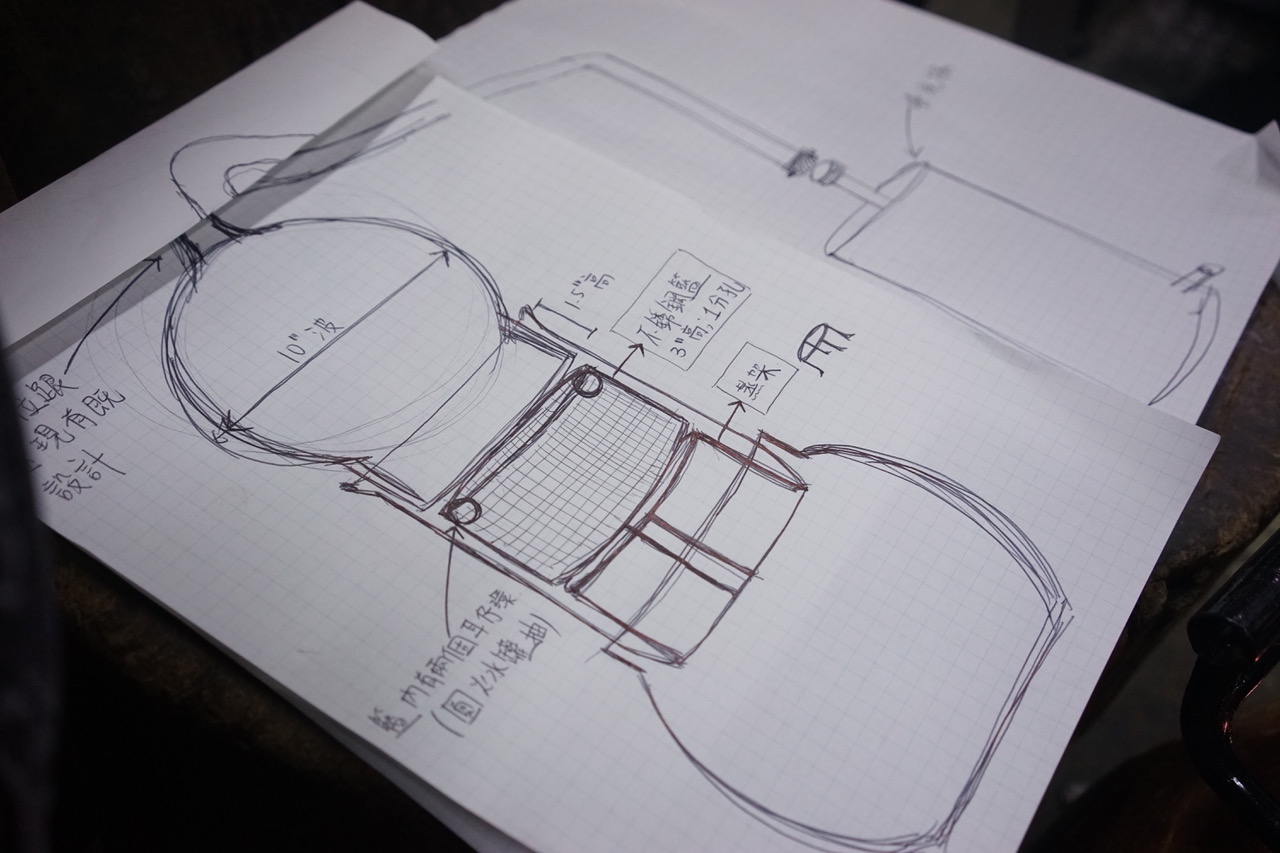

Collaboration with the two Luk masters began with the alembic still that Dimple and Ivan bought from Europe. In the process of creating their gin, Dimple and Ivan used a petite copper still made in Portugal to develop and test the formula. The still comes with a narrow lid and a wide base, in the shape of a gourd. However, this still lacked the most important component for distillation - the thermometer, which prompted the duo to find a solution in Hong Kong.

What started as a simple request to install a thermometer on the still soon became an opportunity to exchange ideas, stories, and skills with the Luk brothers of Ping Kee Copperware. Dimple and Ivan were intrigued by the form and texture of traditional copper herbal tea vessels that Ping Kee had produced, which inspired them to refine the alembic still using traditional copper hammering techniques for herbal tea vessels.

The essence and meaning of craftsmanship lie in exploring with both hands and being flexible from experience. Through the partnership, the Luk brothers were able to bring the young distillers’ vision to life, propelling the art of copper craft forward by introducing new elements to a traditional piece, reinterpreting the traditional craft of herbal tea vessels that once represented the culture of Hong Kong.

STORY OF THE TRADITIONAL CRAFT

The Countless Ties between the Copper Vessel and Still

As Luk Shu Choi recalls, the most glorious period of copperware in Hong Kong was during the 1960s and 1970s. Back in the days, herbal tea was made in the kitchen at the back of the herbal tea shop. Once the hot herbal tea was ready, it would be immediately poured into the giant copper vessels to keep warm. According to folklore, the medicinal properties of herbal tea are most effective when it is served hot. Numerous herbal tea shops commissioned the Luk brothers to create rectangular-shaped copper cupboards, with faucets attached to the bottom for decanting. Some well-off merchants would even order tailor-made herbal tea vessels from them, named "copper gourds" with shiny finishing and the words “Ping Kee Copperware" engraved at the base.

The "copper gourds" are hybrids of the ancient Chinese cauldron (ding) and wine vessel (hu). They are situated in each wing of the herbal tea shop front to keep their secret blends. One of them holds bitter teas like the 24 flavors tea; the other holds sweet teas such as the sugar cane and imperatae drink or chrysanthemum tea. Today, very few herbal tea shops still keep these copper pots, and the masters rarely receive local orders.

Why is copper pot distilling the best way to make gin? Apart from the undeniable aesthetic appeal, copper is exceptionally good at conducting heat, which is the same reason why herbal tea shops love using copper vessels to keep the drinks hot.

While stills can also be made from stainless steel, aluminum and a range of other materials, Dimple and Ivan find that copper is still the best option. Copper is highly malleable and is resistant to corrosion. It has antimicrobial properties, which reduce the possibility of contamination. Copper reacts on a molecular level to remove harsh impurities during distillation. When heat is dispersed evenly over the surface of the still, the result is a more efficient distilling process and better smoother gin.

The Mystery Inside the Gourds

Although stainless steel vessels perform better in heat preservation, copper is believed as a charm to ward off evil spirits. According to folklore, Bhaiṣajyarāja, the Medicine King Bodhisattva, took the gourd containing the elixir and miraculous medicine and went to the secular world to treat the sick. Therefore herbal teapots have taken on the shape of the gourd which symbolizes longevity and blessings to future generations.

The making of liquor is an ancient craft. Since the invention of the alembic copper still, modern techniques have improved the efficiency and quality of distillation. Yet, the art of crafting stills for alcohol distillation has largely remained unchanged, passing down with each generation. As a contemporary distiller, Dimple and Ivan's production process still honors these traditions, as they insist on making quality spirits through proven, traditional techniques.

Even though gin is considered a “Western” spirit, Dimple and Ivan are very proud that they can localize the entire gin-making process, making their gin a truly “Made in Hong Kong” spirit.

MAKING PROCESS

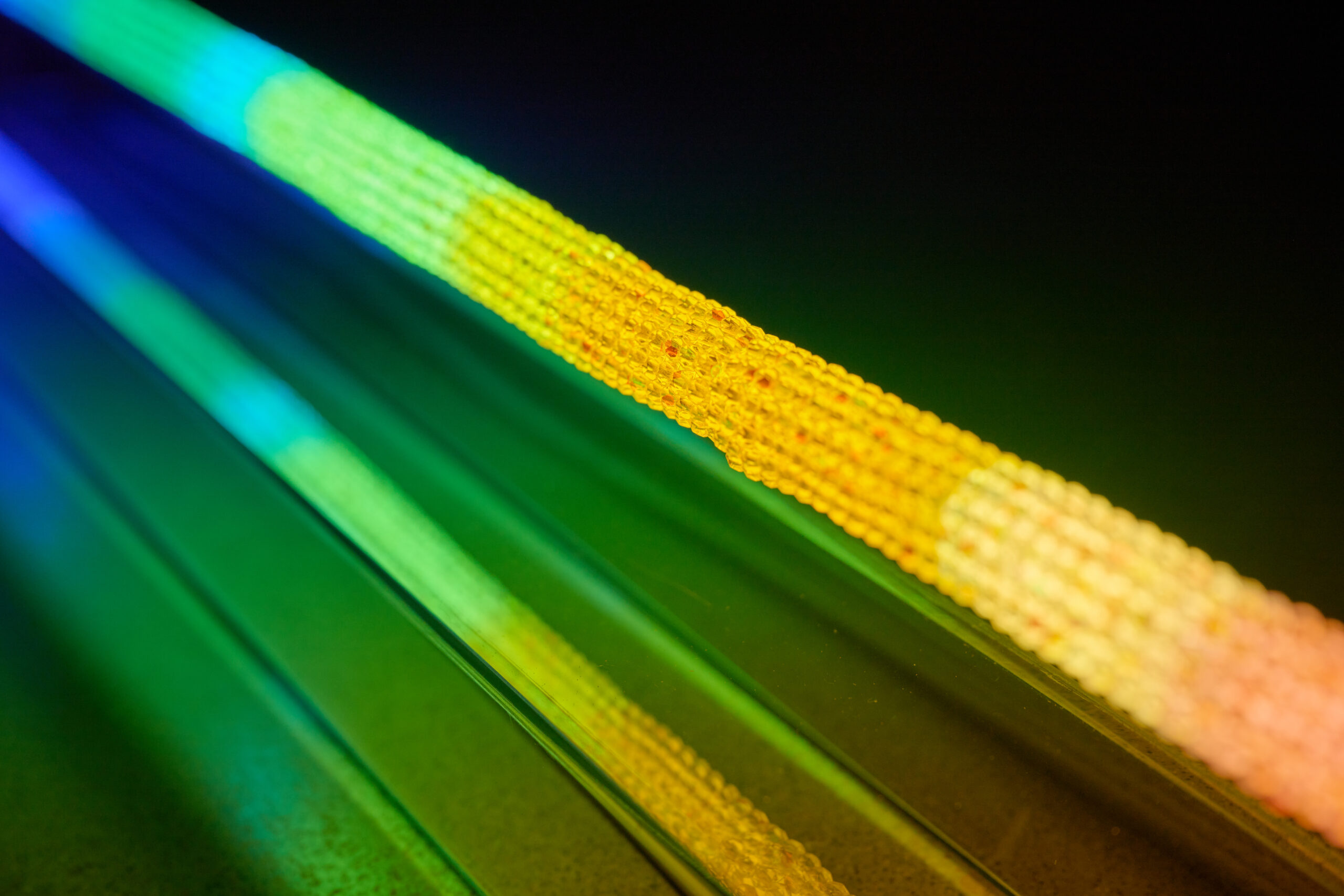

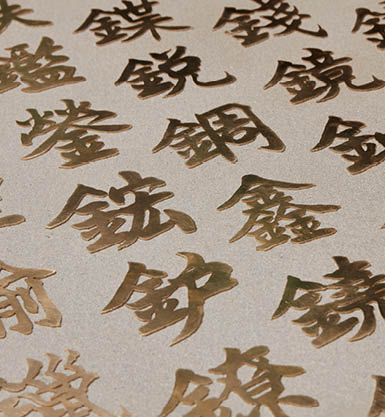

The copperware at Ping Kee is generally forged using copper or brass. In its purest form, copper has a light-red luster, and due to its malleability and high melting point, as well as high viscosity, it is not suitable for casting big containers. Instead, it is combined with other chemical elements to form alloys. For instance, brass is an alloy of copper and zinc, which gives off a golden hue. It has a high density, suitable for making delicate parts.

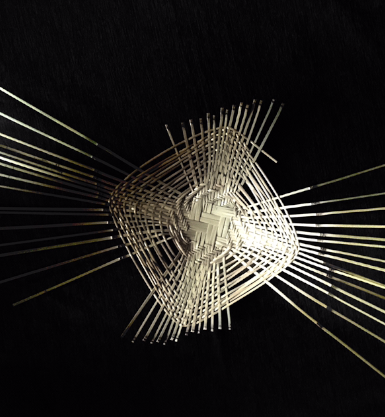

Traditional copper forging is generally performed by hammering a metal sheet placed on an anvil in concentric movements, causing the metal to compress or extend while avoiding the formation of creases. The pots, cups, flasks and stills from Ping Kee Copperware are forged using this technique. The production process starts with a large copper sheet, which is then cut down to size much like tailoring fabric. To fabricate a large copper still takes around thirty days. Both the Luk brothers think the most challenging part is to form the shape. They have to be precise so that it could be connected seamlessly with the body of the still.

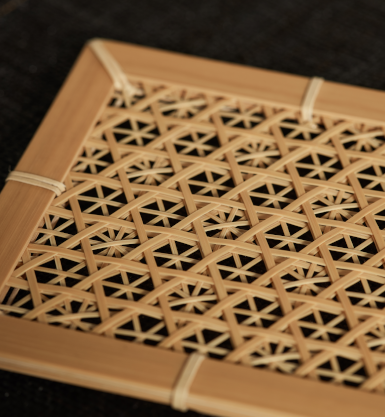

The two craft masters pride themselves on the smooth finishing of their copperware which is a technique passed down from their father, Luk Ping. “Shiny finish represents excellence, as people believed forged patterns to be of poor quality.” However, the Luk brothers are open to a change of mindset according to the times. In recent years, traces of hexagonal forged patterns were gradually found in their work, as some of their customers shared this popular Japanese style with them.

The Luk brothers are humble and studious. They do not merely transplant the popular patterns onto their works. Instead, they incorporate their experience and knowledge to create a unique Ping Kee style. It shows how craftsmanship plays a unique role and evolves with the times, and the relationship between traditional craftsmanship and cultural trends in different regions.

A piece of copperware requires a continuous and repetitive forging process followed by welding and polishing, and every single step demands concentration and finesse. The Luk brothers believe that handcrafted copperware also requires patience and deep thoughts on the design in addition to the demands of techniques to bring out the soul of a particular piece of work.

Artworks from same series

OTHER WORKS FROM EXHIBITION

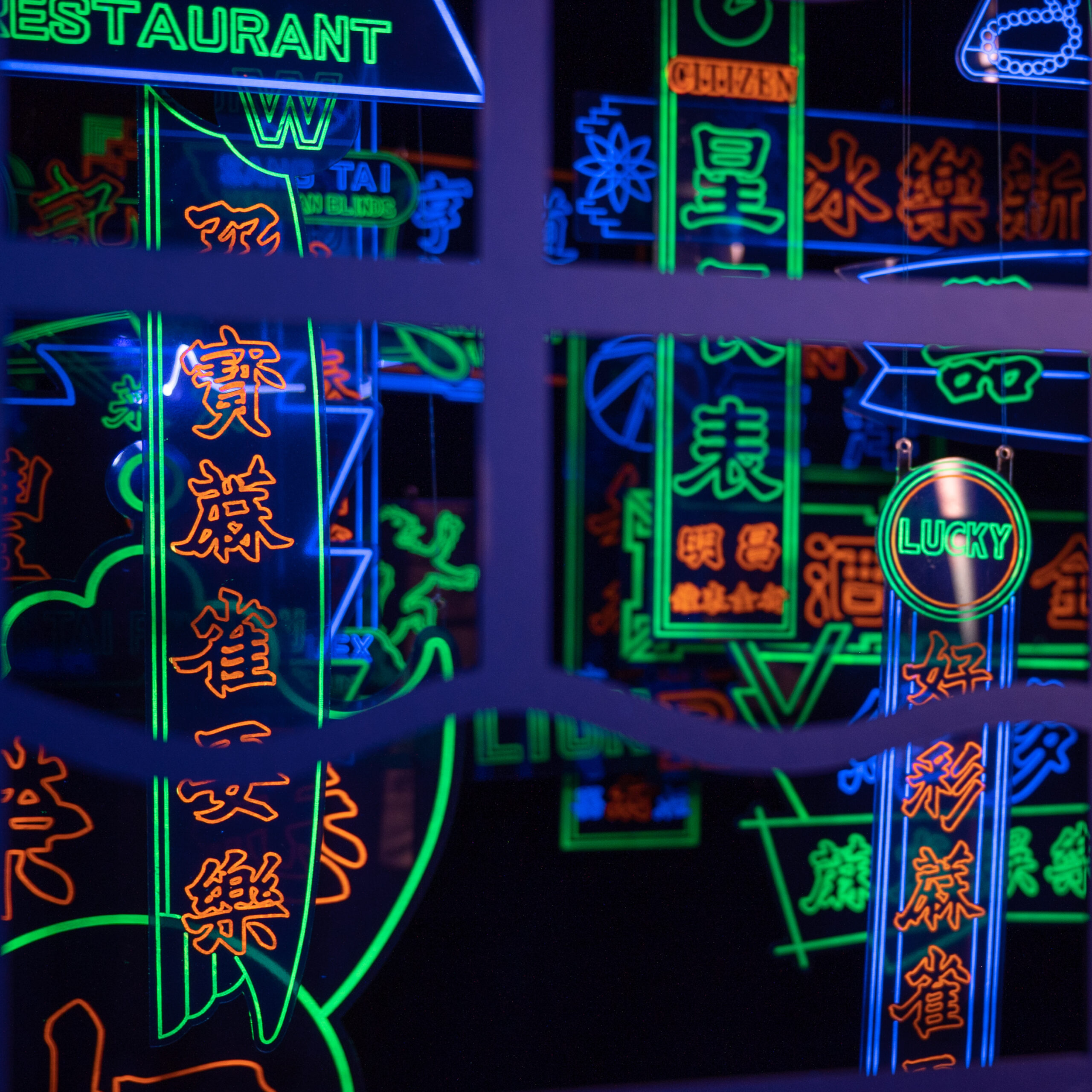

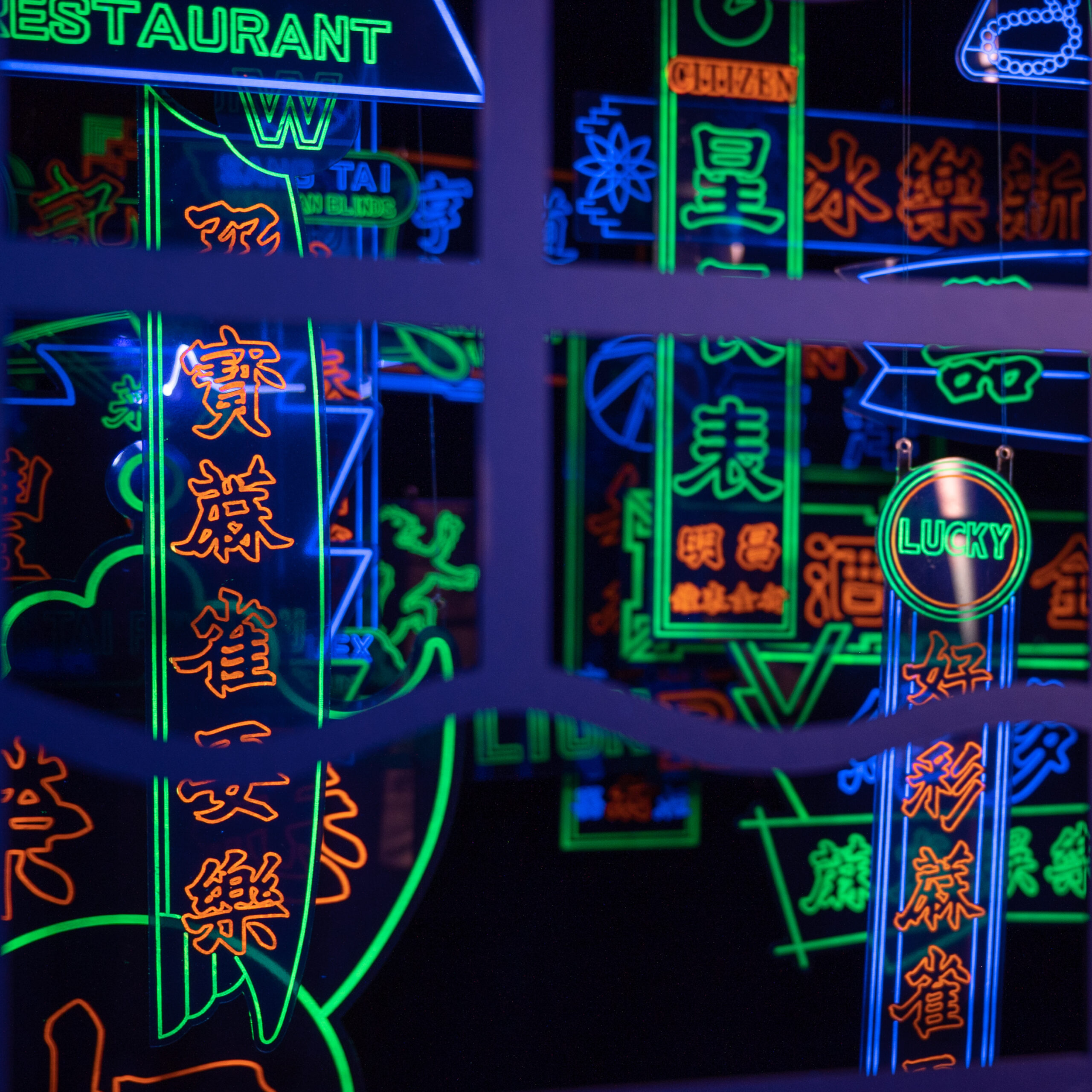

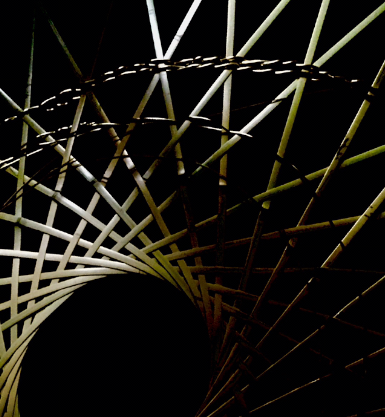

Auspicious Horizons

Yue Kee Rattan Factory & Ahung Masikadd & Barnard Chan & Cecilia Lai