Mirror

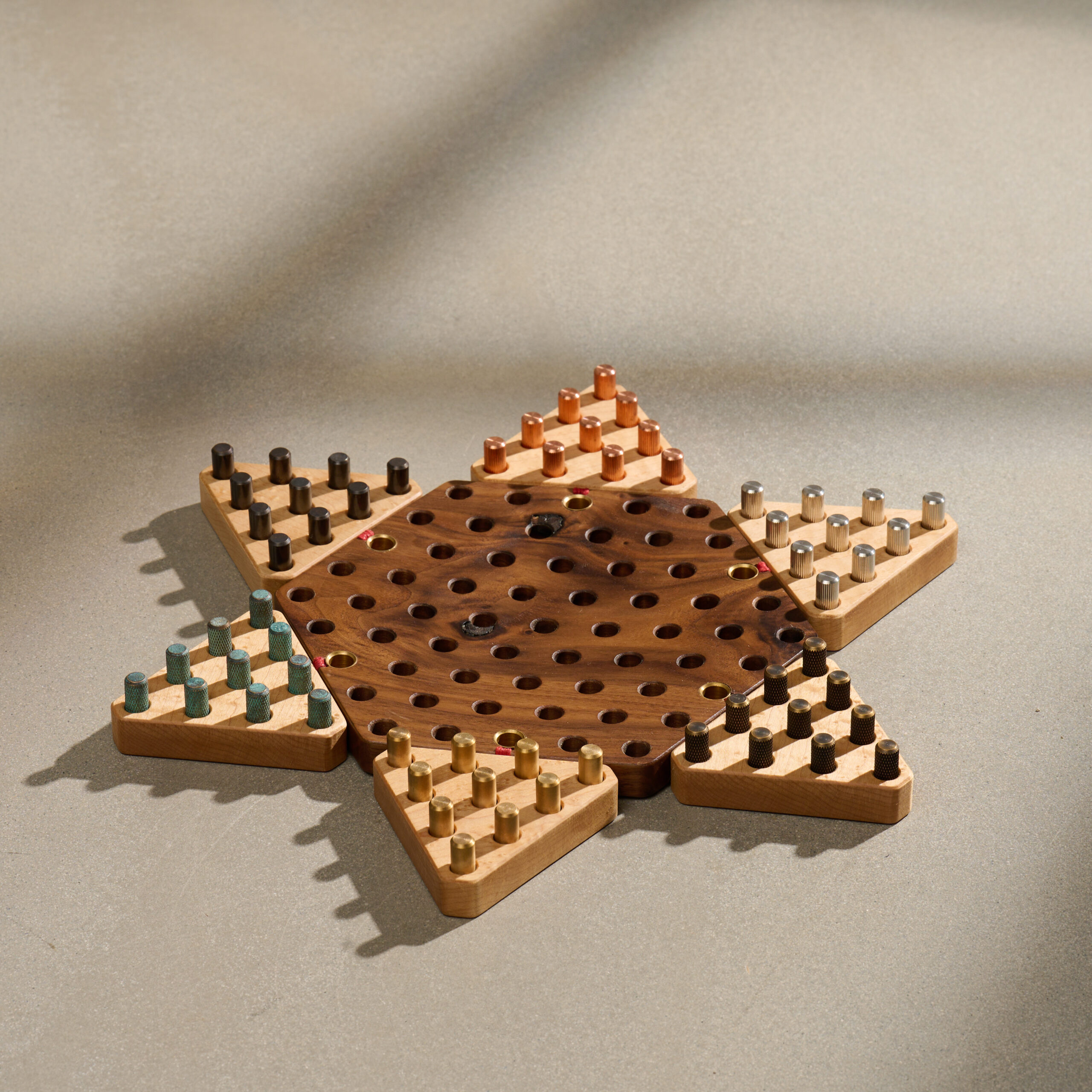

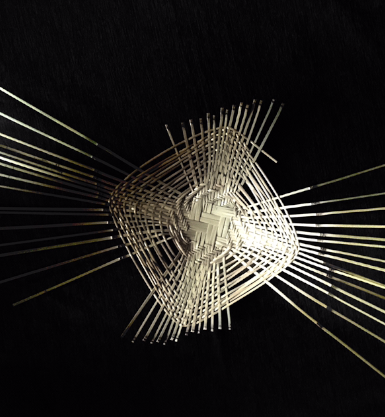

The copper mirror created by Fanson Lam explores the relationships between desires, death and identities through human sculpture.

As early as 3000 BCE, the use of bronze started to develop in China and bronze mirrors have played a significant role in reflecting, both literally and symbolically, the culture of the Chinese. They transcended their mere practical usage to become an important moral icon.

“With a mirror, one can see whether he is properly attired; with history as a mirror, one can understand the rise and fall of a nation; with men as a mirror, one can see whether he is right or wrong.” Emperor Tang Taizong of the Tang dynasty once said.

STORY OF THE TRADITIONAL CRAFT

In Hong Kong, the traditional casting industry mainly produces copper or iron parts for machine components. Being the apprentice of Master Liu Wing Sheung, sculptor Fanson Lam hopes to bring copper casting to a new aesthetic level through the collaboration. He discusses the feasibility of his creative idea with Master Liu. With over fifty years of experience, Master Liu's craftsmanship carries Fanson's creation.

Harnessing his creativity as a sculptor, Fanson incorporates Master Liu’s traditional metal casting techniques into new designs. Through endless discussions and experimentations, their complementary skills continue to bring traditional metal casting techniques into contemporary objects in our daily lives.

MAKING PROCESS

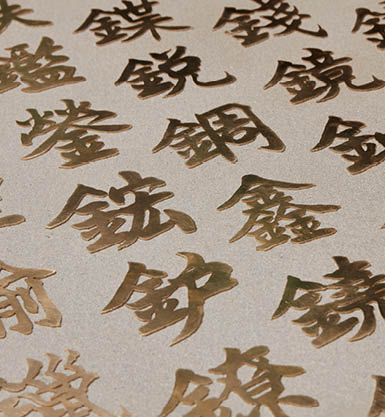

There are two major ways of casting: sand casting and lost wax casting. Liu specializes in the latter and the making process is as follows:

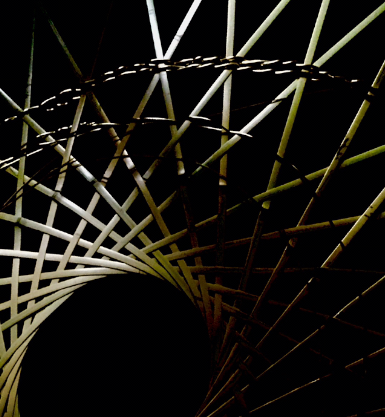

First, a sculpted clay model is covered with silicone gel, forming a mold after being air-dried. Liquid wax is poured into the mold and after cooling, the wax will harden to become the desired form. A complex form has to be divided into several parts and they are welded together to become a wax tree.

The wax tree is then placed in a steel container where the plaster is poured into. Hardened plaster is heated so that all the wax wrapped around the plaster is melted and a hollow plaster mold is formed.

Copper is melted at a high temperature of over 1000°C and injected into the plaster mold. The plaster mold is cooled by immersing in water, enabling the copper inside to solidify. The plaster is then removed and an oxidized patina could be created by dipping the work into a special chemical solution. After coloring and finishing, the work is heated repeatedly and coated with a wax layer to enhance durability.

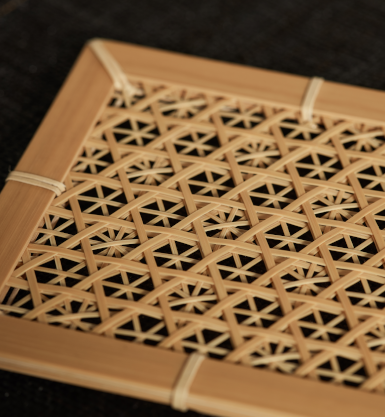

Artworks from same series

Craftsman

OTHER WORKS FROM EXHIBITION