Coffee Drip Pot

The coffee drip pots are coated with a tin layer, paired with a rattan woven handle, while the gooseneck spout provides more flow control. There are two designs and one can be used directly over the stove.

STORY OF THE TRADITIONAL CRAFT

Before starting Fuukidou, Takeshi’s grandfather worked and honed his skills at the most renowned copperware workshop – Gyokusendo, where Takeshi had also worked for two years. In 1954, Takeshi Fujii’s grandfather founded Fuukidou and mainly made vases and Yuwakashi (kettle). Meanwhile, Takeshi’s father preferred making different varieties of vases and high-quality cooking pots. Takeshi treasures the time he worked with his father and grandfather. Their spirits and dedications motivate him to aim high and continue to make better products. “The person I was yesterday made me who I am today; what am I going to be tomorrow? Thinking about it makes me want to do my utmost.”

As a third-generation metalsmith, Takeshi Fujii wants to create copperware that would create an amazing experience for the users. Originally, Takeshi did not favor any particular type of copperware and simply wanted to make copperware that its owners would treasure. When he met the owner of Bnei Coffee from Tokyo, his interest in making copperware for coffee began.

Through Bnei Coffee, Takeshi understood better how the tools for making coffee relate to the actual customer needs and experience. While Takeshi still makes Fuukidou’s signature utensils, he has taken it upon himself to make copper drip pots and servers, which would enhance the brewing experience. Nowadays, quality coffee drip pots with thin spouts and coffee servers have become one of Fuukidou’s signature items.

Thin spout coffee pots are favored for baristas in brewing coffee with the traditional Nel Drip method. The precise control of water stream, roast levels and grind size of beans are crucial to the fragrance of coffee. The angle, thickness, curvature of the spout, and the handle must all be considered in making the pot. These factors change the taste of the final brew by dictating the amount of strength a barista uses when pouring water into the coffee grounds. With constant conversations, Takeshi creates unique coffee pots with traditional techniques.

Takeshi thinks that craft is to fully utilize materials and techniques while producing functional yet beautiful works. Takeshi once repaired a copper coffee pot made by another craftsman at the request of a client. The difficulties and challenges in the repairing process remain a memorable experience that Takeshi appreciates deeply.

In Tsubame-sanjo, many hardworking and talented youngsters are engaged in metal crafts. Takeshi is greatly heartened by the friendly community of young craftsmen who learn and encourage one another with great humility. Takeshi hopes to pioneer new techniques and a style of his own going forward. He passionately believes that his devotion will soon bear fruit.

MAKING PROCESS

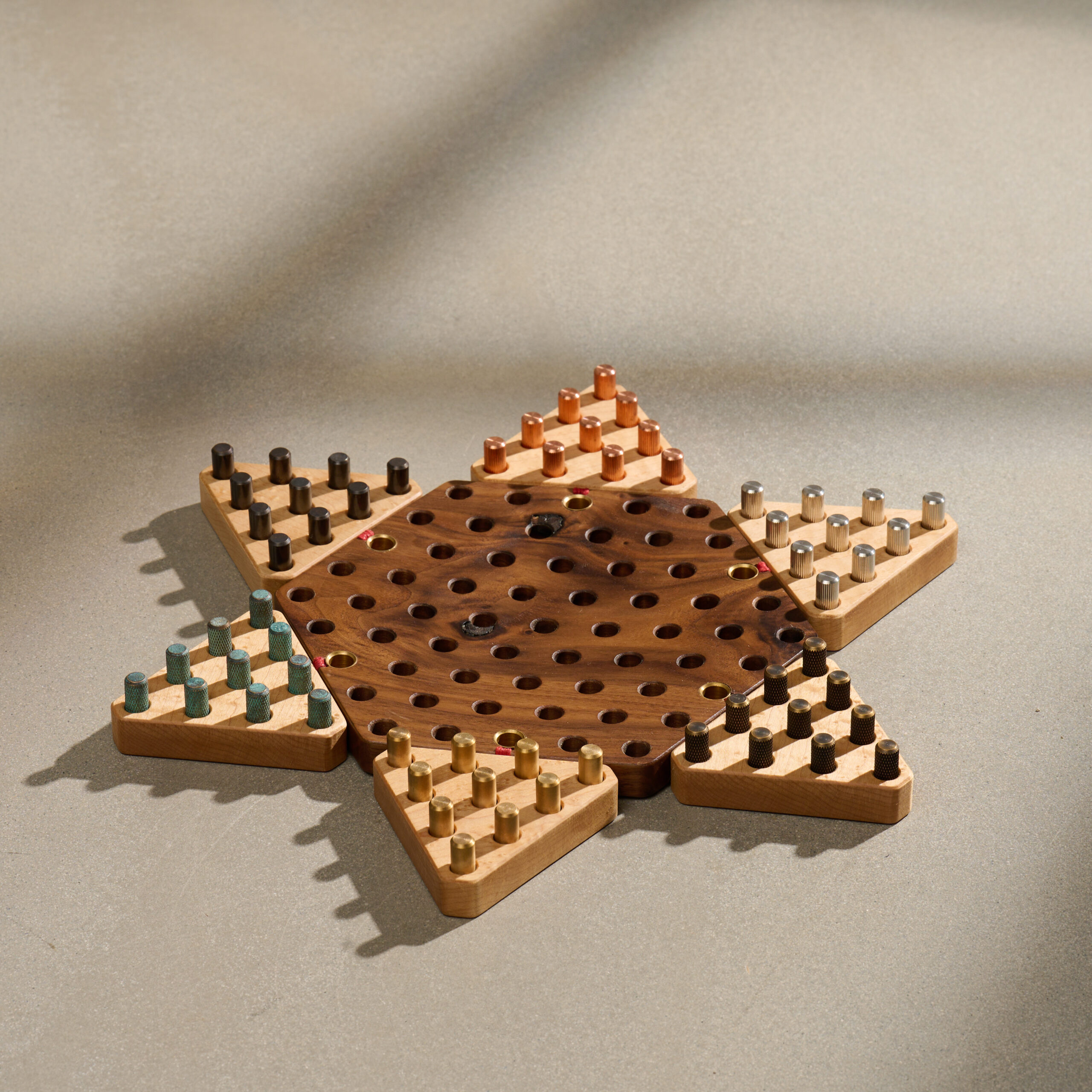

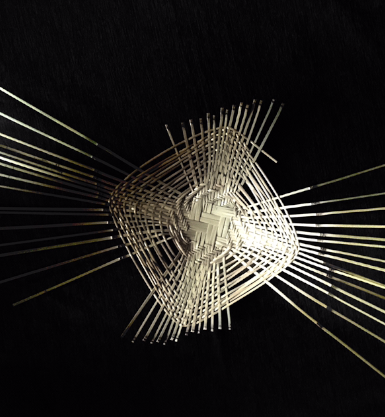

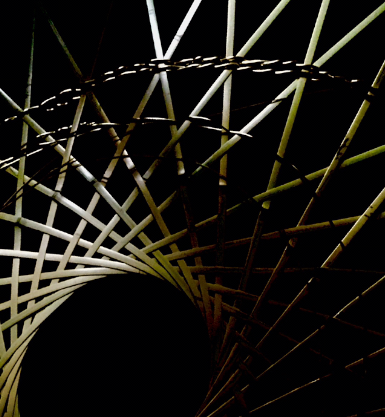

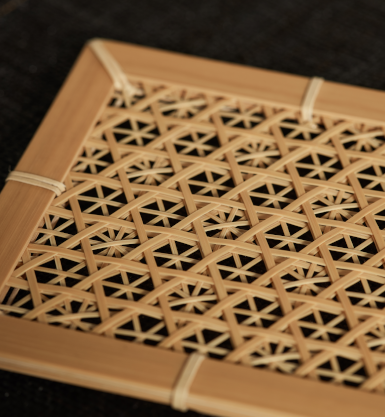

Fuukidou uses the Tsubame-tsuiki technique of forging and metal spinning to create its copperware. The body of the copperware is first raised with either a metal or wooden hammer from a piece of copper sheet. As each pound hardens the material, heat was applied to soften the copper again via annealing. Usually, this takes a few rounds to create the ideal shape of the main copperware body. Other delicate parts are then further refined, using a range of metal hammers, combined with toriguchi rods and ategane (small metal pillars).

After completing the body, craftsmen of Fuukidou would coat a thin layer of tin on the interior. The copper body is first heated to the tin's melting point. The tin coating will be melted and spread evenly across the surface and then set aside to cool. Finally, the spout and handle are welded onto the copper pot.

Artworks from same series

Craftsman

OTHER WORKS FROM EXHIBITION